Expansion joints in use: Cost-effective complete solutions for sustainable processes

Our expansion joints are in demand in all industries. Applications range from plant engineering and power plant construction to process technology, from the paper and pulp industry to the chemical industry. The interaction between material expertise, intensive consulting and production expertise that Frenzelit offers benefits our customers. We produce sustainable solutions that function smoothly in your process – for many years. That’s why Frenzelit has such a good reputation among countless industrial companies around the world.

The following practical examples demonstrate our wide range of services.

Mobility Energy Wood, paper and pulp industry Chemical and petrochemical industry Glass, steel and aluminum industry Food and drinking water industry Machine manufacturing and plant engineering

Mobility

Shipbuilding

Gas turbine exhaust systems

- Type 1.131/03

- Temperature: 570 °C

- Pressure: 40 mbar

- Movement: 50 mm in all directions

- Application: GT modules for civil shipping and marine

Diesel exhaust systems

- Type 1.011/IS

- Temperature: 650 °C

- Pressure: 60 mbar

- Movement: axial: 25 mm, lateral: 15 mm

- Application: Marine

Sealing in gas duct and ship design

- Type 1.422

- Temperature: 500 °C

- Pressure: 5 mbar

- Movement: axial: 40 mm, lateral: 10 mm

- Application: Yachts

Gas tank sealing

- Type 1.201

- Temperature: 150 °C

- Pressure: 100 mbar

- Movement: axial 40 mm, lateral: 10 mm

- Application: LPG tankers

Metal expansion joints for exhaust systems

- Type: FR-UN DN900

- Temperature: 600 °C

- Pressure: 500 mbar

- Movement: axial: 20 mm, lateral: 35 mm

- Application: LPG tankers

Commercial vehicles

Rail vehicles

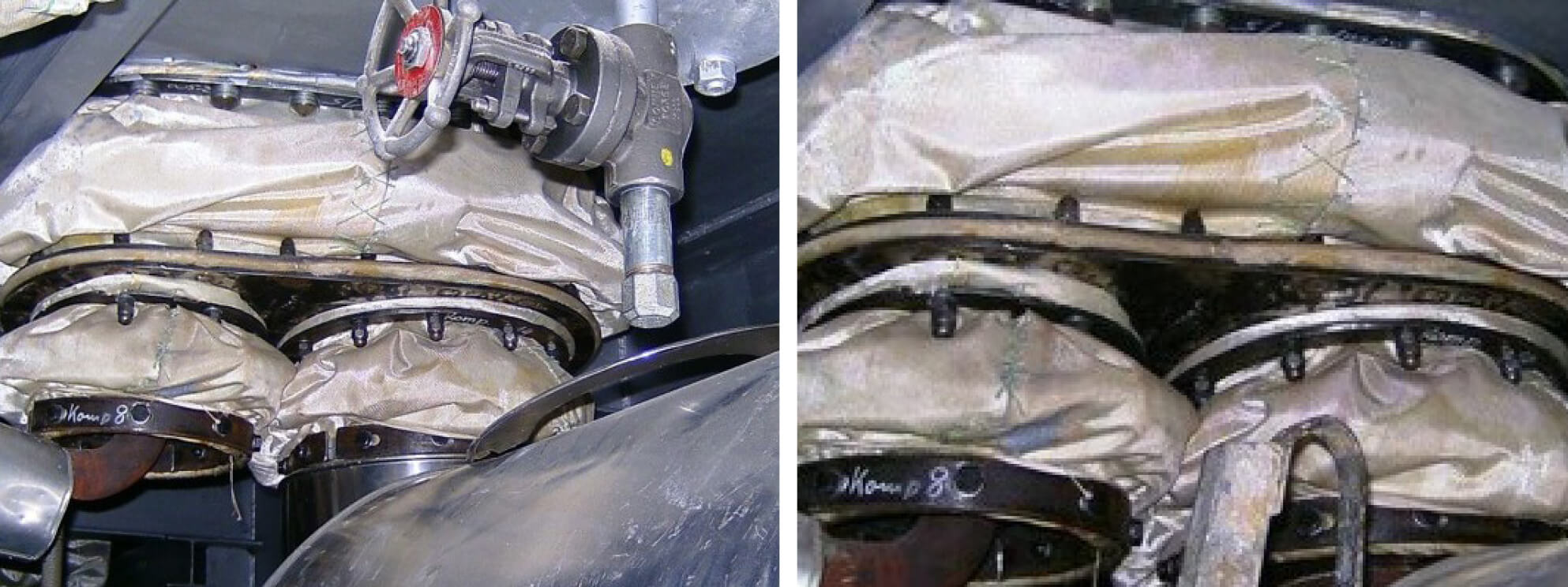

Rubber expansion joint for engine ventilation on a train bogie

- Size: 600 x 580 mm

Energy

Coal-fired power plant

Cooling tower seal for coal-fired power plant

- Specially designed fabric expansion joints

Coal-fired power plant

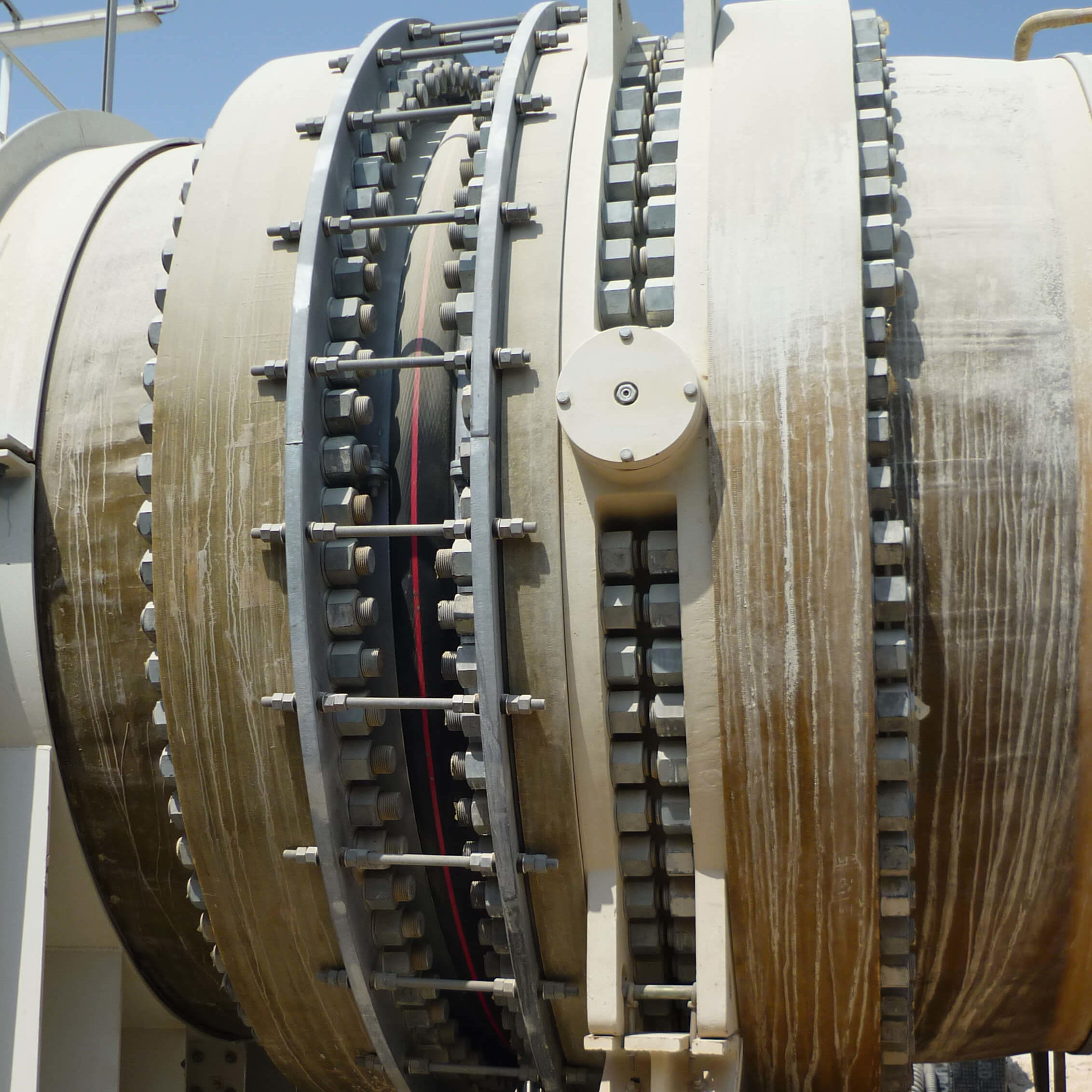

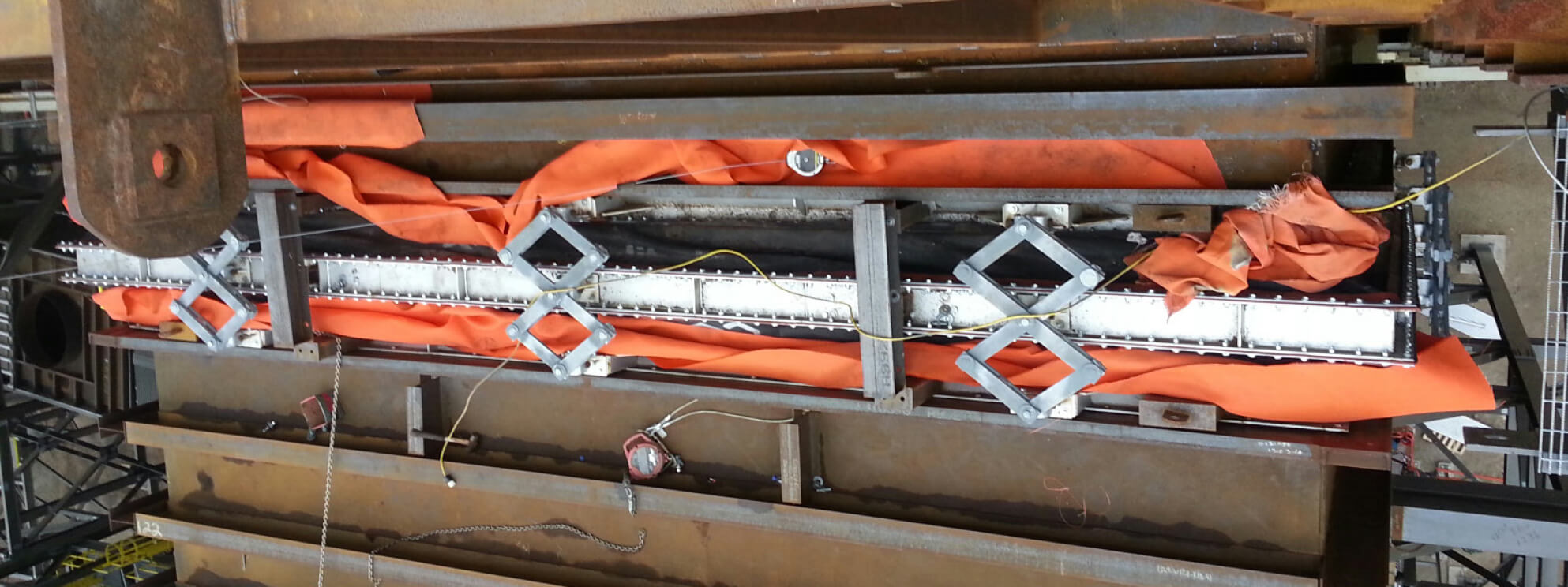

Expansion joint with pantograph control guide in exhaust gas cleaning

Expansion joints for large movements, wind loads

Coal-fired power plant

Expansion joints with pantograph control guide at boiler outlet

Expansion joints for large movements due to wind loads

Coal-fired power plant

Gas turbine power plant

Gas turbine exhaust system for high temperatures

Expansion joint in GE LM2500 gas turbine diffuser with increased ambient temperature of approx. 150 °C.

Gas turbine power plant

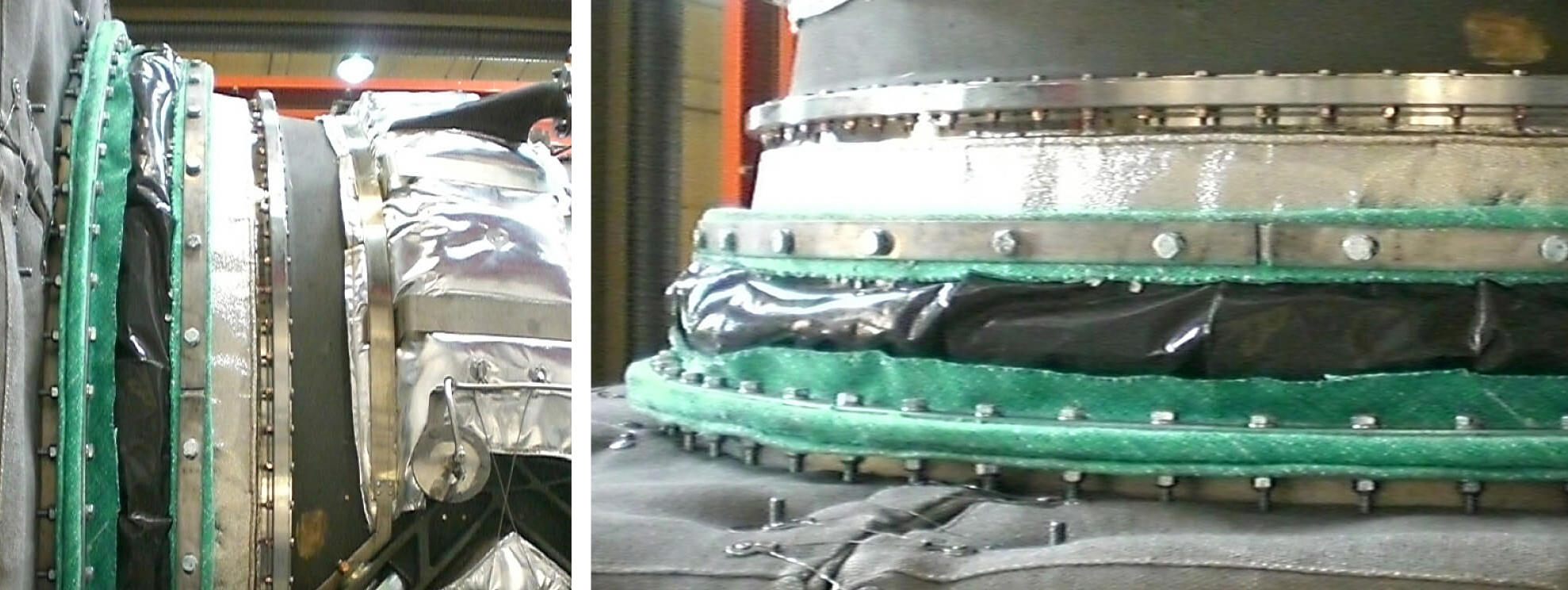

Gas turbine exhaust system for high temperatures

The most highly stressed expansion joint in the exhaust system directly at the turbine outlet with an exhaust gas temperature of max. 700 °C and an axial compression of minus 110 mm with simultaneous lateral shifting of 50 mm. The expansion joint is located directly at the junction of the outer-insulated turbine flange to the inner-insulated exhaust gas duct.

Gas turbine power plant

Multi-tube boiler seal at waste heat boiler of gas turbine

- Specially designed fabric/non-metallic joints

Gas turbine power plant

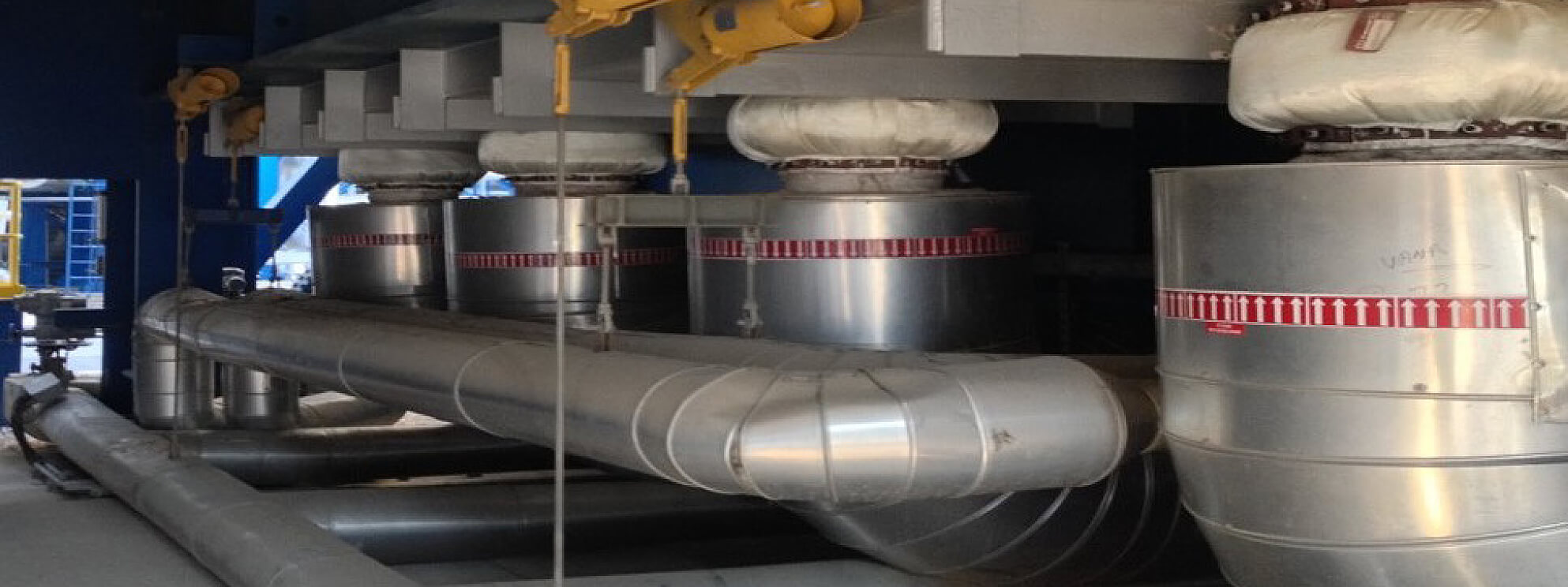

Double fabric expansion joint as boiler seal for waste heat boiler of gas turbine

- Specially designed fabric/non-metallic joints

Gas turbine power plant

Fabric expansion joint as boiler seal for waste heat boiler of gas turbine at base

Bolted connection for high temperatures at base

Gas turbine power plant

Fabric expansion joints as boiler seal for waste heat boiler of gas turbine

Frenzelit fabric expansion joints for high axial and different lateral movements

Steam turbines

Dog bone rubber expansion joint at condenser for steam turbines

+/- 1 bar pressure, tape length 40 m

Waste incineration plants

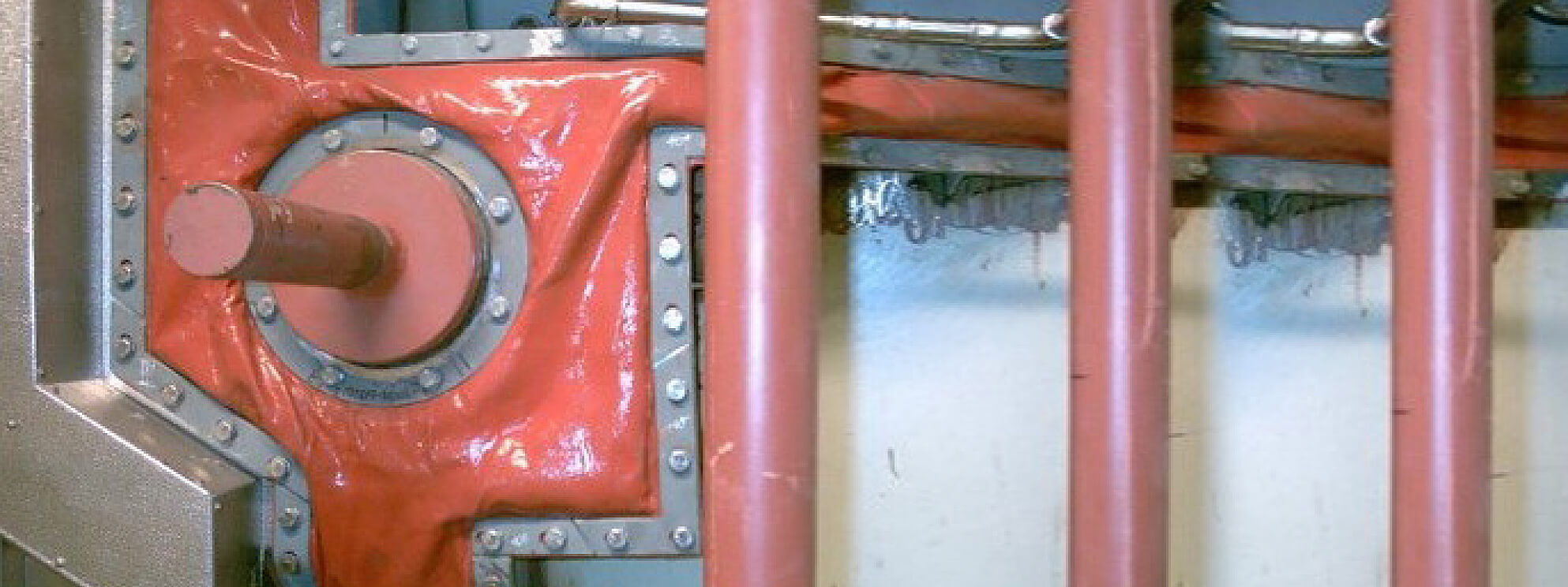

Header pipe breakthrough at incinerator boiler with chute entry

- Specially designed fabric/non-metallic joints

Waste incineration plants

Corner segment at incinerator boiler

- Specially designed fabric/non-metallic joints

Wood, paper & pulp industry

Paper industry

Expansion unit for hood supply and exhaust air for a paper machine

Paper industry

Double bellow with intermediate pipe, as well as a special construction of the holding rod to catch the intermediate pipe for paper machines

Chemical and petrochemical industry

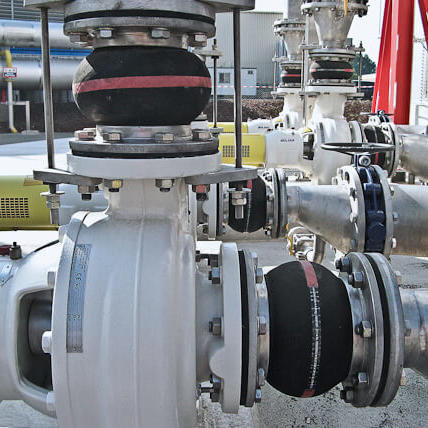

Desalination plants

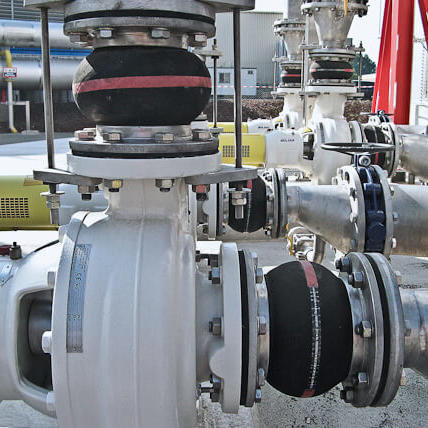

Process water/wastewater

Flexible rubber expansion joints

DN 125 / 10 bar

DN 80 - 4000 / max. 2,5 bar

Process water/wastewater containing solids

Abrasion-resistant rubber expansion joint hose with support for wastewater containing solids

Glass, steel, iron and aluminum industry

Continuous annealing furnaces

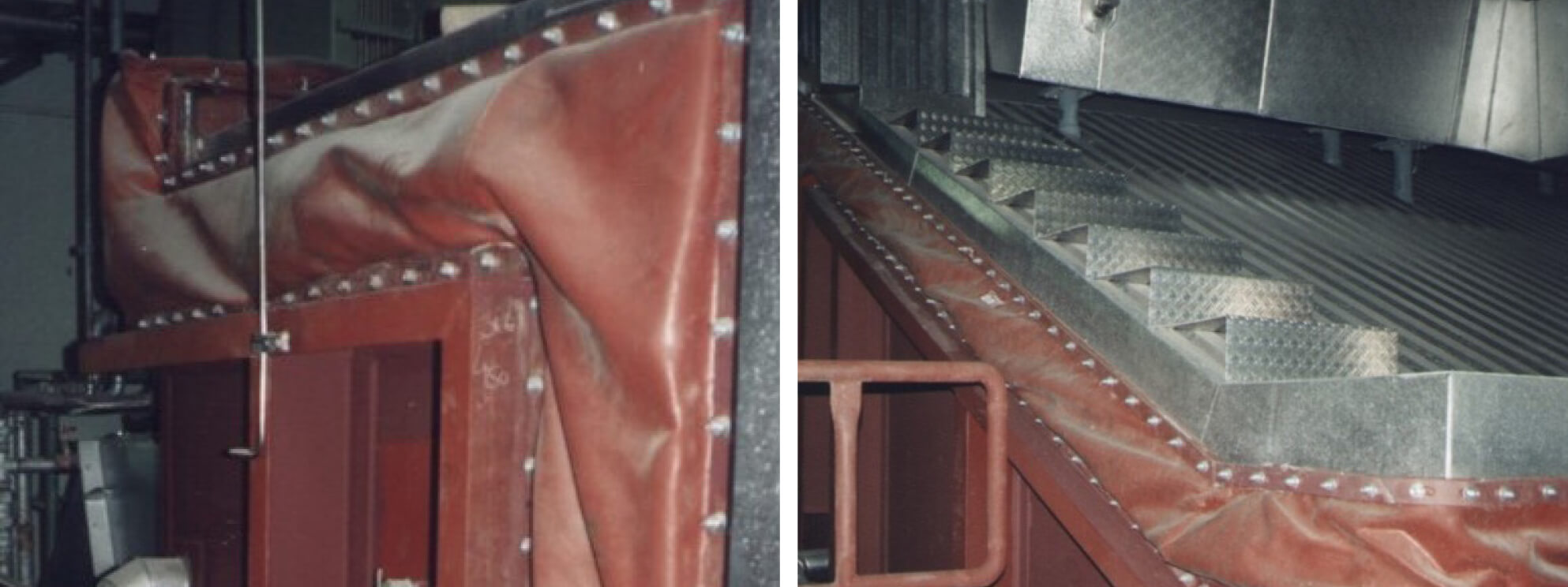

Annealing furnaces

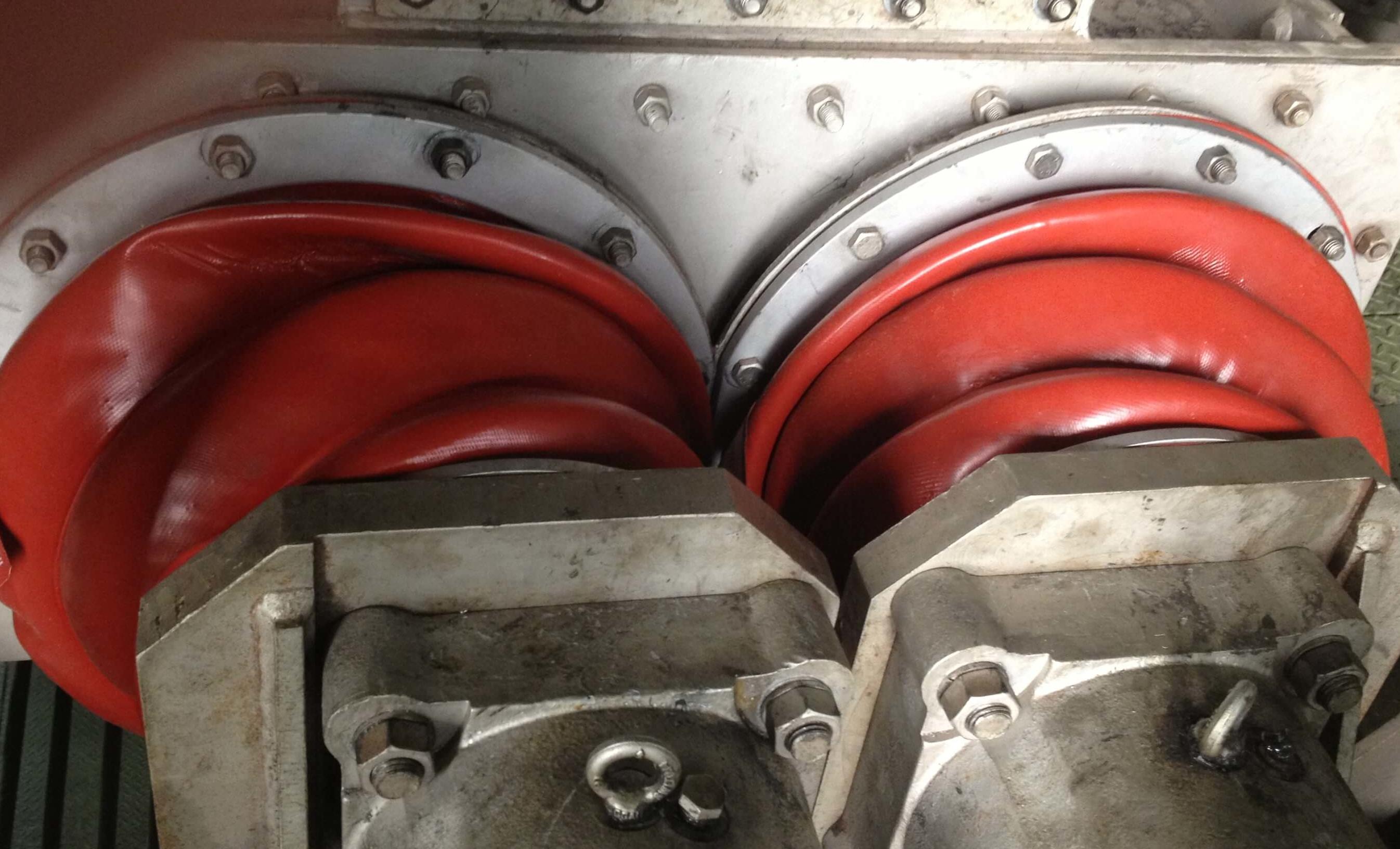

Tandem expansion joints at the final cooling section of an annealing furnace

Rubber expansion joints at the final cooling section an annealing furnace

Up to DN 240 / 320

Strip galvanizing lines

Copper mines

Rubber expansion joint with PTFE lining for outlet of a washer in a copper mine

Double expansion joints at the final cooling section of an annealing furnace

Non-metallic expansion joints at steering rolls for continuous annealing furnaces

Food and drinking water industry

Drinking water industry

Flexible rubber expansion joints

DN 125 / 10 bar

DN 80 - 4000 / max. 2,5 bar

Machine manufacturing and plant engineering

Bulk material loading devices

Expansion joints - Challenged on many fronts

Frenzelit expansion joints prove their excellent properties in numerous process steps in strip galvanizing lines and during the continuous annealing of metal sheets.