Metal Expansion Joints

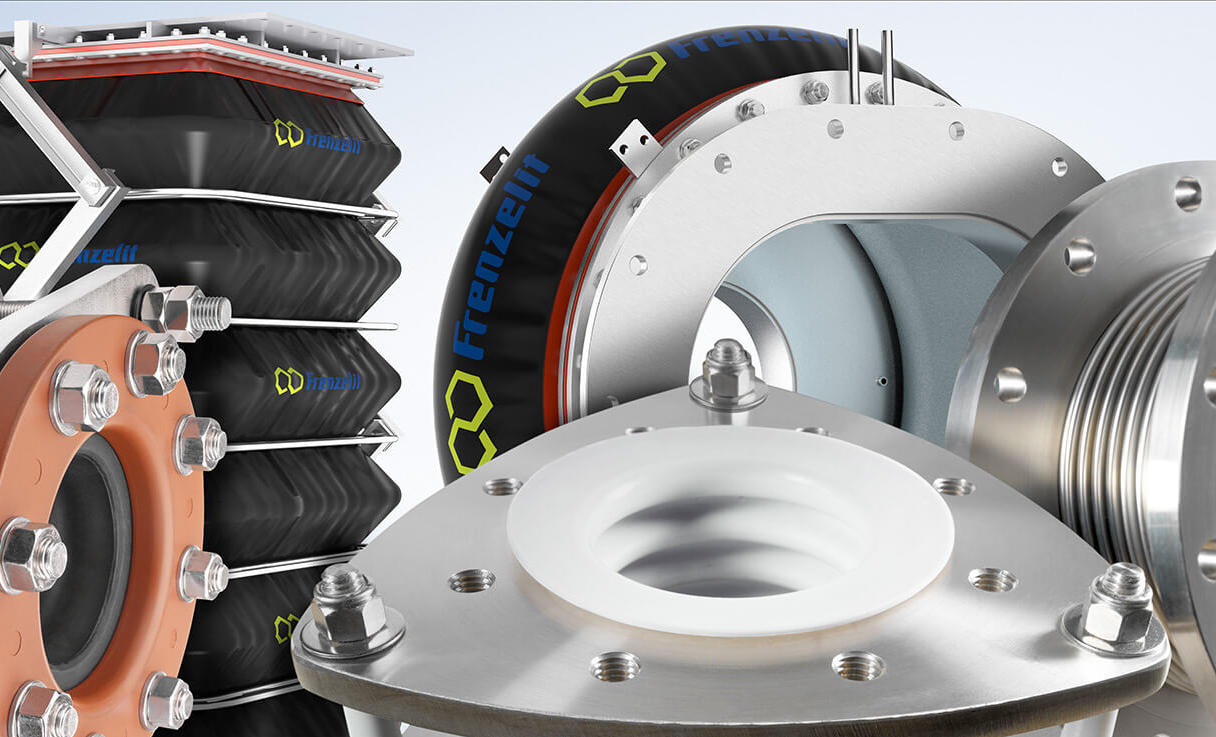

Frenzelit offers you the complete range of metal expansion joints for both round and rectangular pipe cross-sections from a single source.

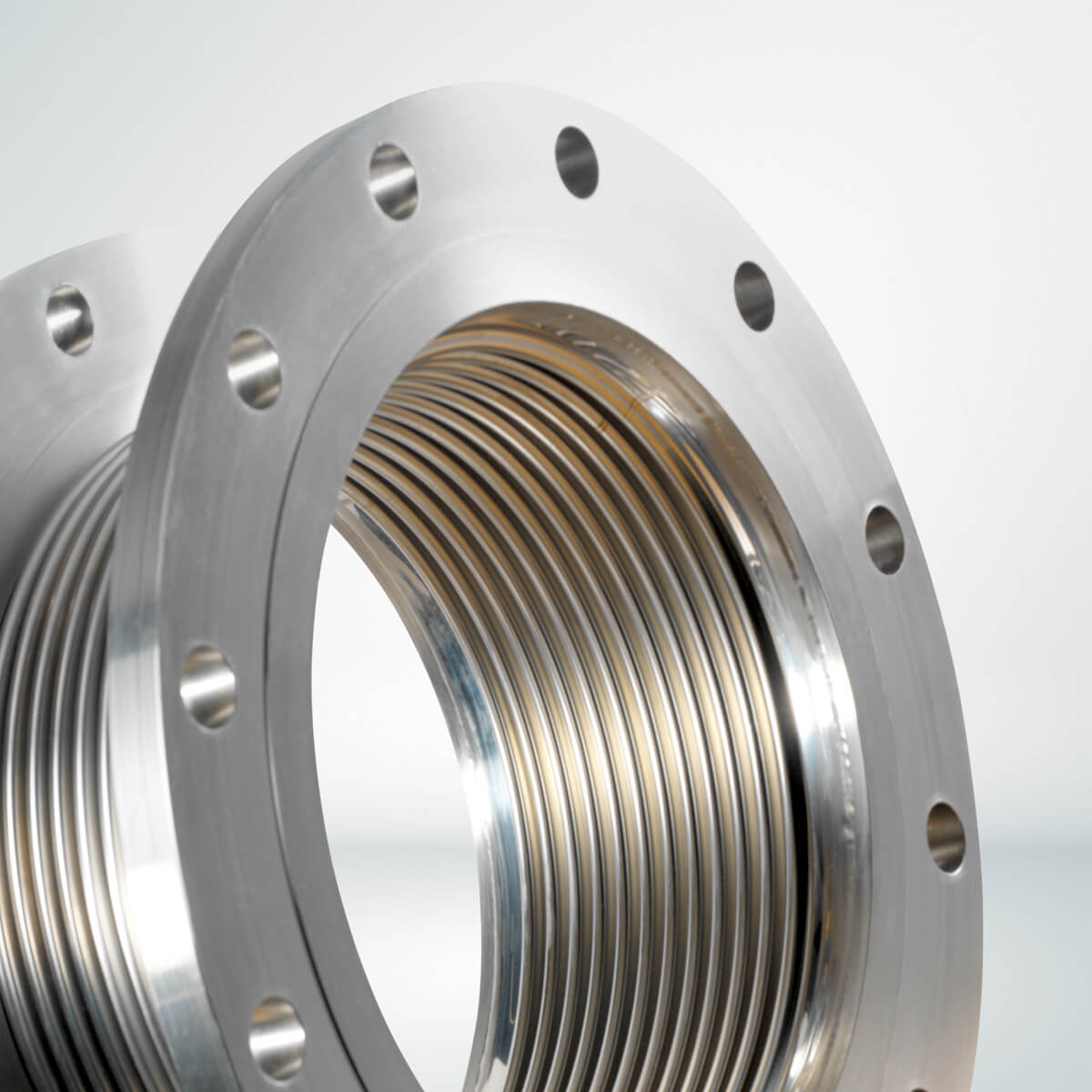

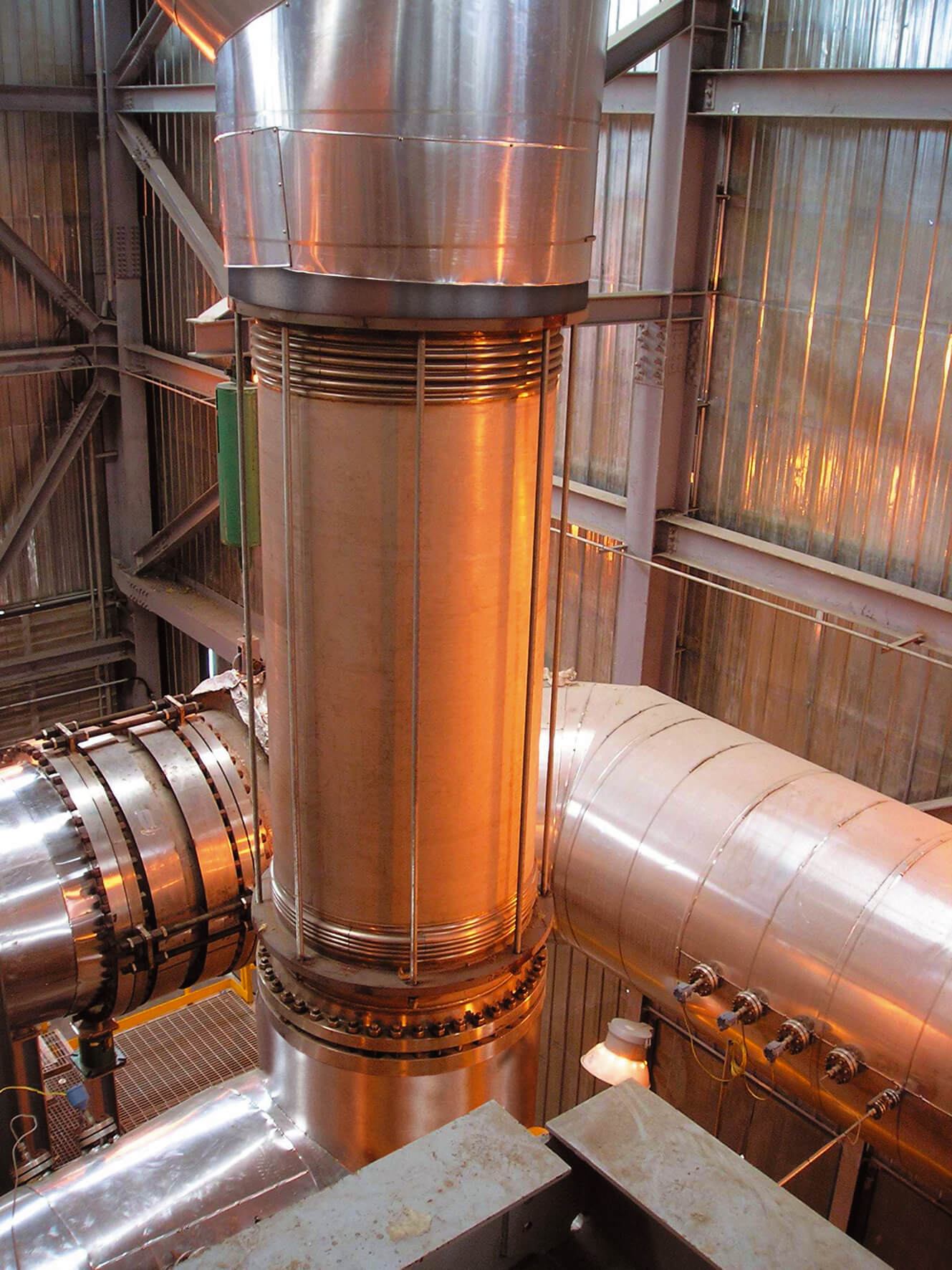

Round expansion joints

- Single-layer bellow

- Multilayer bellow

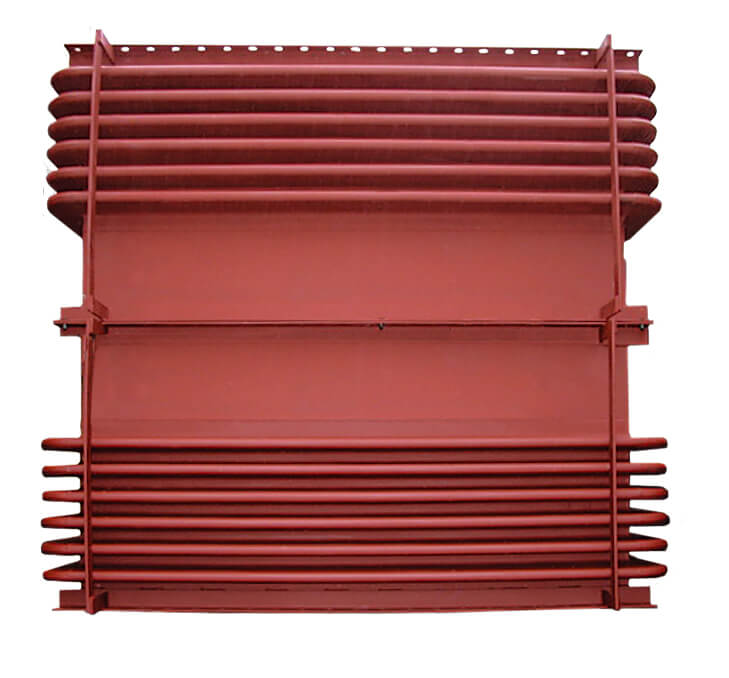

Rectangular expansion joints

- Single-layer bellow

Single-layer lens-type expansion joints

- Single convoluted bellow

- Multi convoluted bellow

Materials

- The bellows, welding ends and flanges are manufactured out of stainless steels, creep-resistant steels and structural steels according to specifications or according to the specific requirements.

- To ensure short deliver times, we also always keep high-quality heat and corrosion-resistant stainless steel in stock.

Metal expansion joints – system solution:

Lateral metal expansion joints with tensioning

Other system solutions for metal expansion joints:

Certifications, approvals and tests:

Application areas:

- Exhaust Gas Cleaning Systems

- Wastewater Treatment

- Strip Galvanizing Lines

- Biomass Power Plants

- Coating Systems

- Fertilizer Production

- Dedusting Plants

- Filter Systems

- Conveyor Systems

- Glass Industry

- Gas Turbine Power Plants/CCPP

- Annealing Plants

- Refrigeration

- Power Plants

- Radiator Bridges

- Cooling Towers/Smokestacks

- Paint Finishing Systems

- Food Industry

- Mills

- Waste Incineration Plants

- Food Industry

- Emergency Power Generators

- Pumps

- Paper Processing

- Petrochemical Plants

- Pharmaceutical Industry

- Process Air Systems

- Flue Gas Cleaning Systems

- Reduction Furnaces

- Residue Incineration

- Rail Vehicle Manufacturing

- Marine Propulsion and Turbines

- Shipbuilding

- Vibrating Screens and Vibrating Conveyors

- Sintering Plants

- Steelmaking

- Dryers

- Drying Plants

- Scales

- Ventilators/Induced Draft Systems

- Heat Exchangers

- Water Treatment Plants

- Pulp Production

- Cement Plants

- Sugar Industry

Application examples

Certifications, approvals and tests:

Certifications, approvals and tests:

Service

Expansion joints must withstand loads like the system component or pipe itself absorb and additional stress, movements, oscillations or vibrations in axial and/or lateral direction – while ensuring operational safety.

You may already have a very good idea what your expansion joint should look like. Or an application that you want to further develop. A partnership with Frenzelit allows you to realize your ideas according to your system-specific requirements.

We offer you the following:

Frenzelit engineers work together with your design department to develop a technically and economically feasible solution that meets your demands. Our experts are at your disposal in all project phases to develop fabric, non-metallic and elastomer expansion joints, PTFE and multi-laminated PTFE expansion joints as well as rubber and metal expansion joints for your system. We are with you every step of the way – from planning and production to installation and maintenance – for the life of your system.

Personal, on-site consulting ensures that your employees stay focused on what they do best, saves valuable resources and gets you the results you need faster. We develop, design or optimize expansion joints in collaboration with your team based on your specifications – so you can rest assured that they will continue to meet tomorrow’s demands. That’s why our motto is “creating hightech solutions”.