novaphit®

Graphite gaskets

High-quality gaskets made from expanded graphite

The novaphit® product family comprises a range of high-quality expanded graphite flat gasket materials – made in Germany. novaphit® gaskets are reliable and durable even at the outer application limits, which makes them the perfect choice wherever excellent efficiency and performance paired with maximum process reliability are required.

novaphit® gaskets have the following properties:

- Temperature range from -200°C to 550°C

- Universal chemical resistance

- Excellent adaptability to flange unevenness

- Insensitive to changing loads

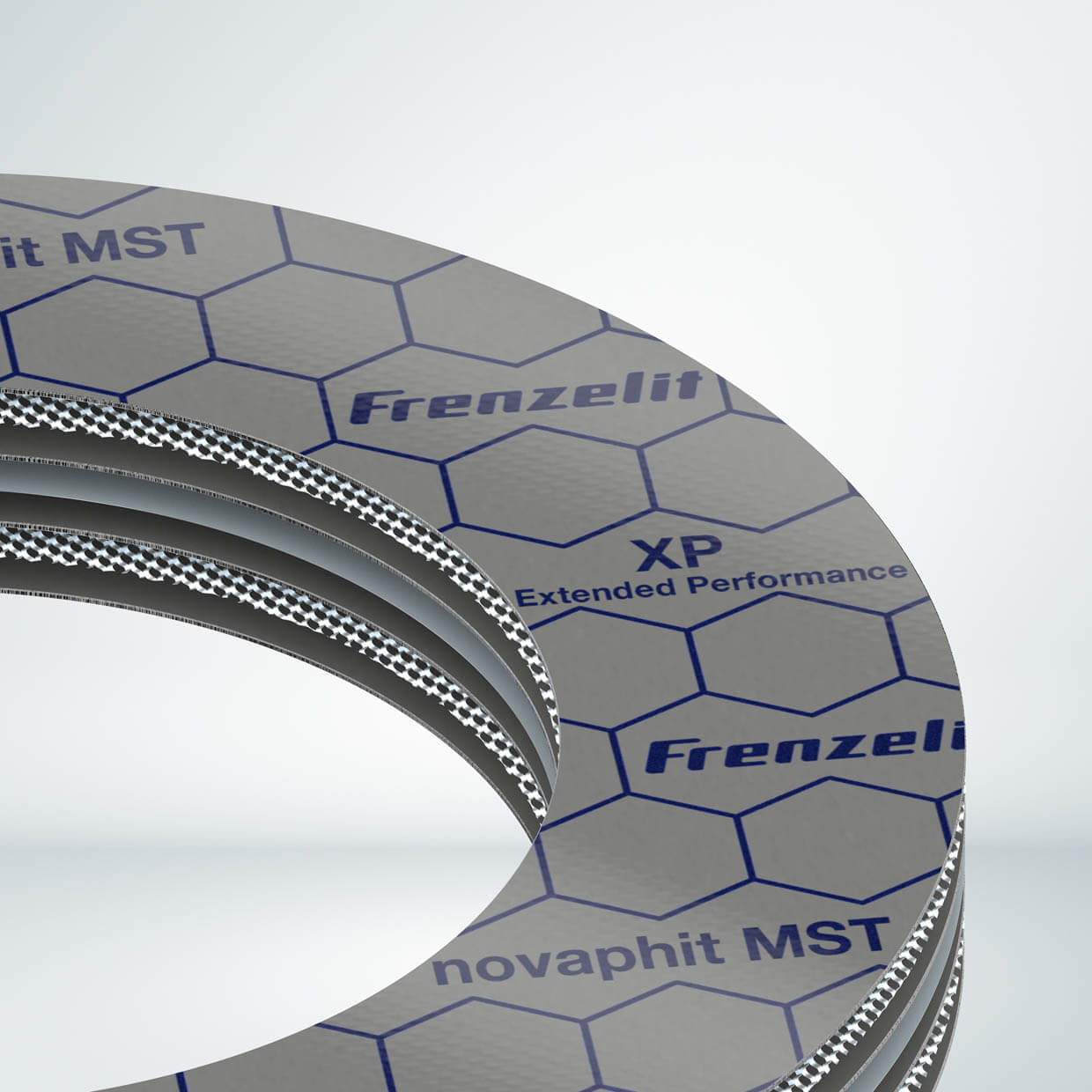

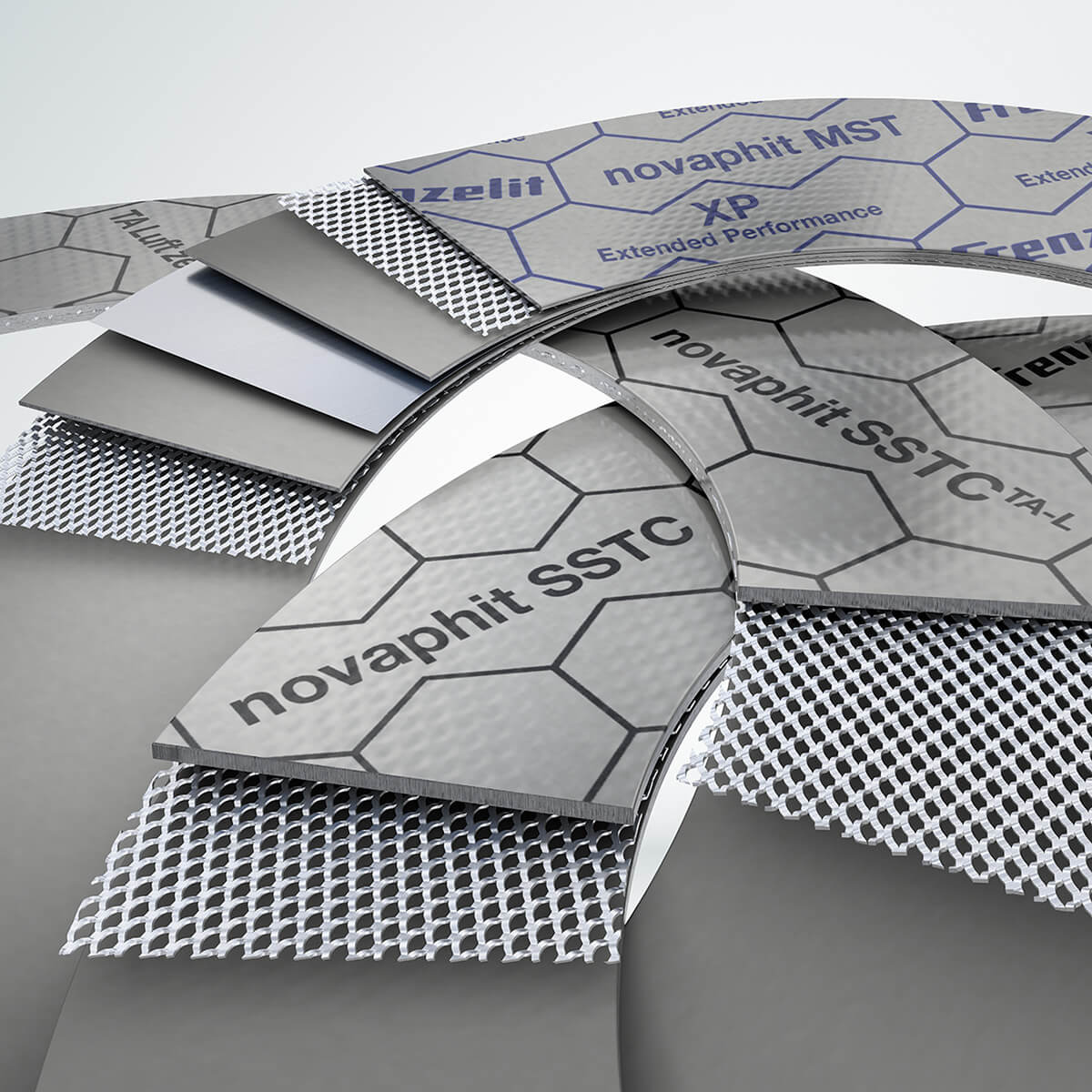

Graphite is perfect as a gasket material for higher operating temperatures, yet it has only limited inherent strength due to its material composition. A metal insert is therefore advantageous for secure handling because it improves the mechanical stability of the gasket material. Stainless, acid-resistant steel (1.4404 / 316L) is used in this case. The selected expanded metal insert has an intelligent three dimensional geometry, which additionally has a positive effect on the sealing properties of the graphite. The concept of using an expanded metal insert in the novaphit® SSTC gasket material has proven so effective that it is also used for advanced materials such as novaphit® MST.

Even products that have proven their effectiveness over decades can be further improved: XP technology for novaphit® gaskets sets new benchmarks for efficiency and performance. This novel technology makes graphite more resistant to oxidation, which considerably improves the long-term temperature stability of the gaskets. The benefit for the user is longer machine running times and greater plant reliability.

But that’s not all. XP technology has another revolutionary effect: It significantly reduces graphite deposits on the sealing surfaces, which greatly facilitates gasket removal. This means no more cleaning of the flanges, or only basic cleaning is necessary. This saves valuable time and protects the sealing surfaces of the flanges. The XP material is permanently effective and resistant to chemicals throughout the entire temperature range of graphite gaskets.

XP technology benefits at a glance:

- Increased oxidation resistance

- Anti-stick properties (resistant to temperature exposure)

- Huge time savings when replacing gaskets

- Less downtime

- Prevents flange damage

Future applications with hydrogen

In the future, Frenzelit will mark products suitable for hydrogen applications with a registered H2 - logo. Materials and products marked as "H2 - approved" have been tested in both resistance and leakage tests with the medium hydrogen and their suitability has been proven.