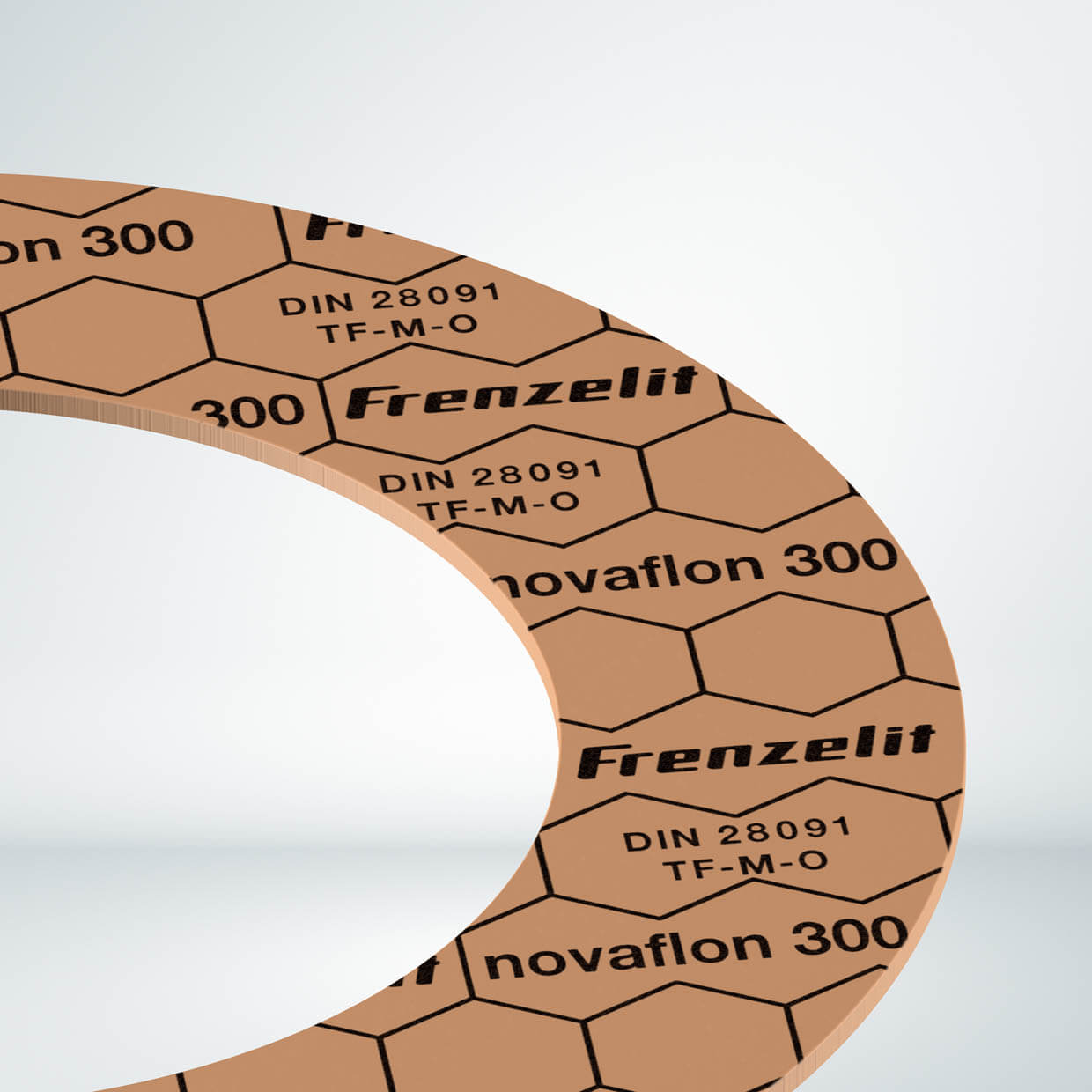

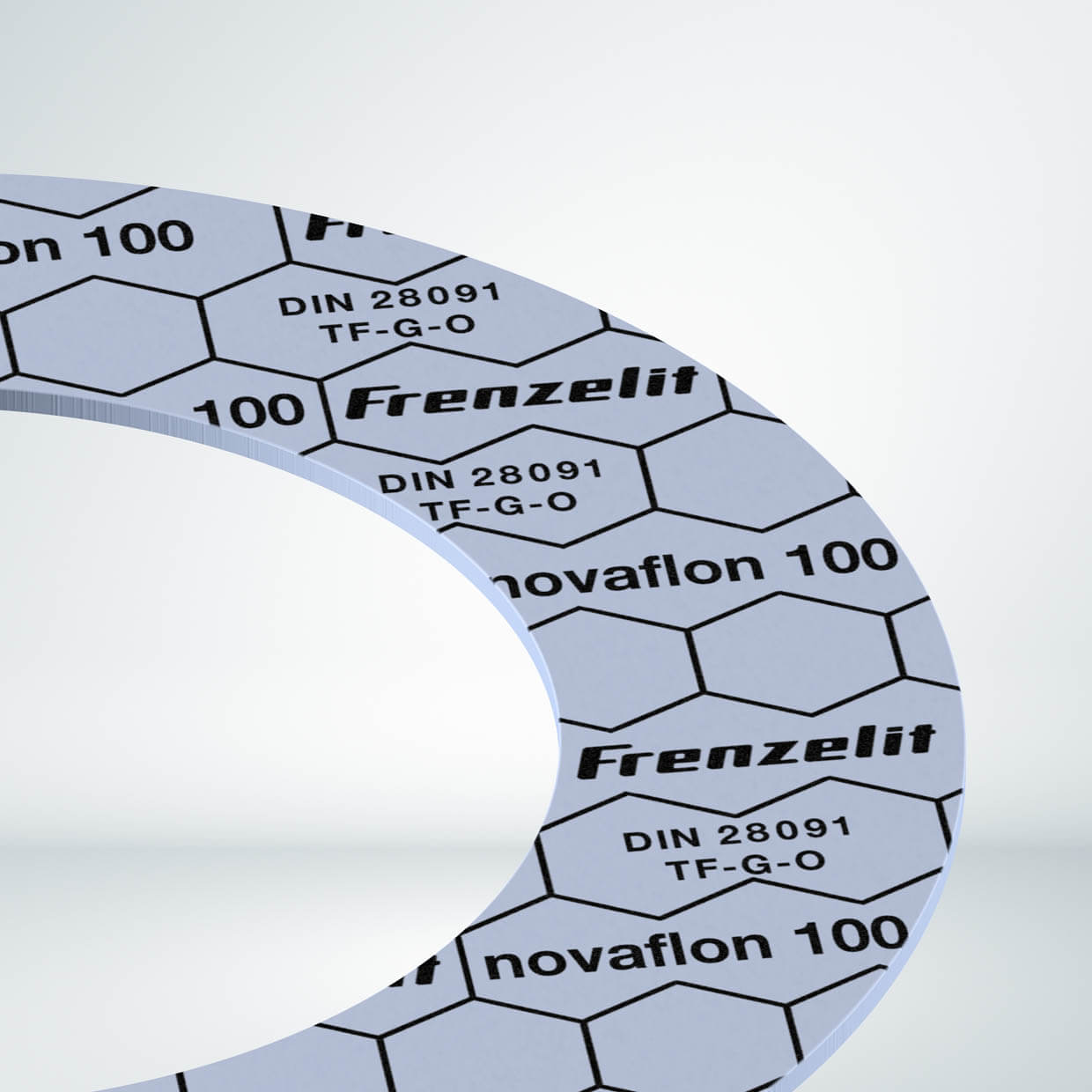

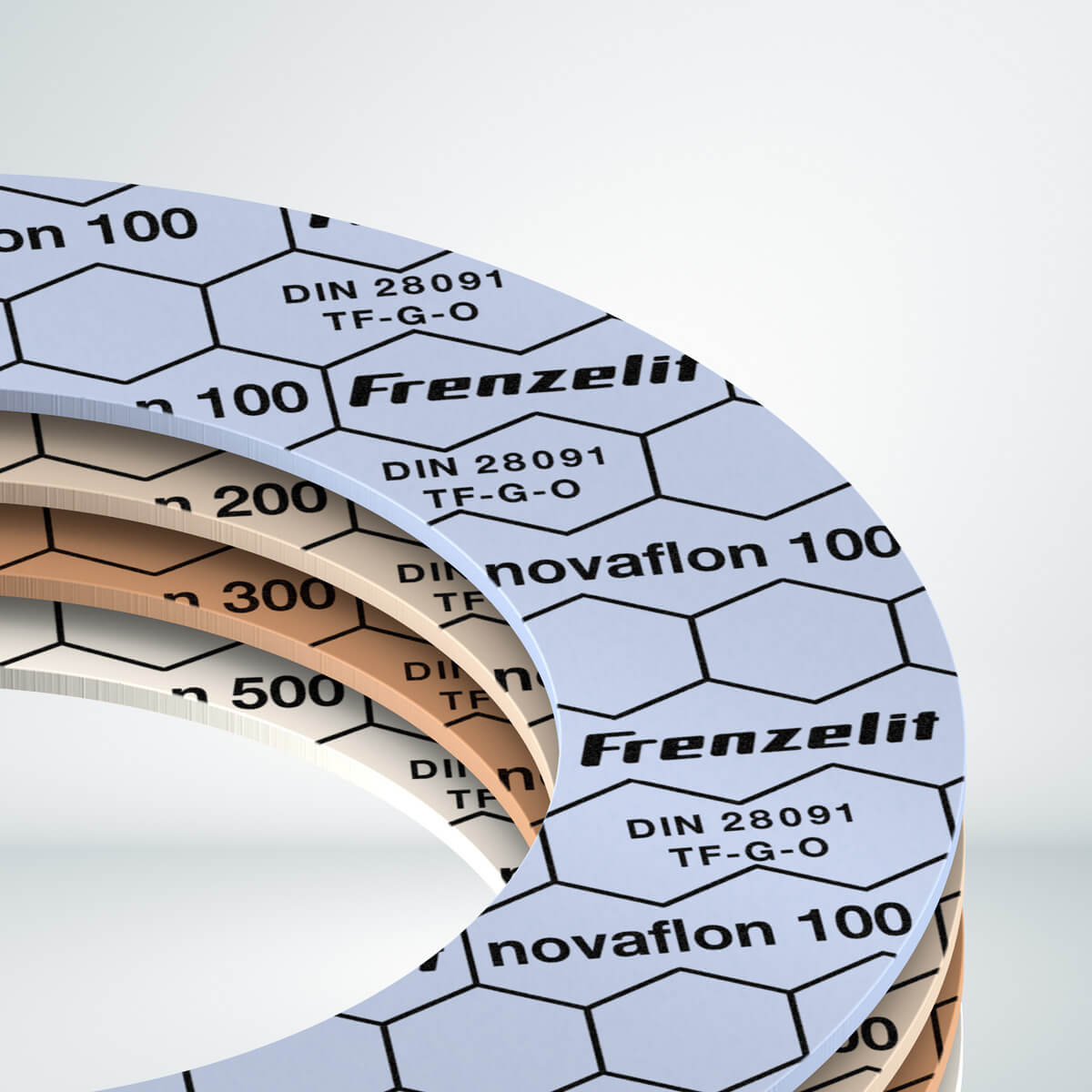

novaflon®

PTFE gaskets

Effective PTFE gaskets with universal media resistance

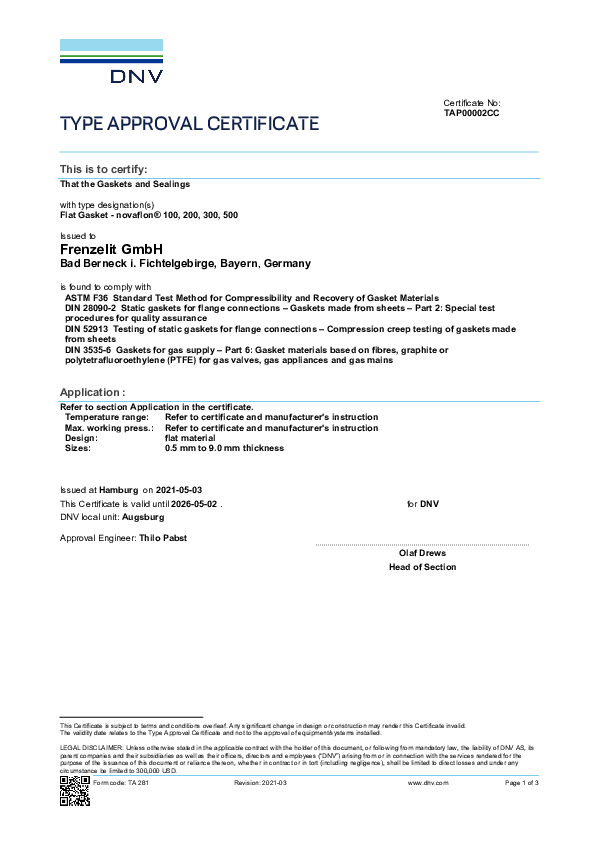

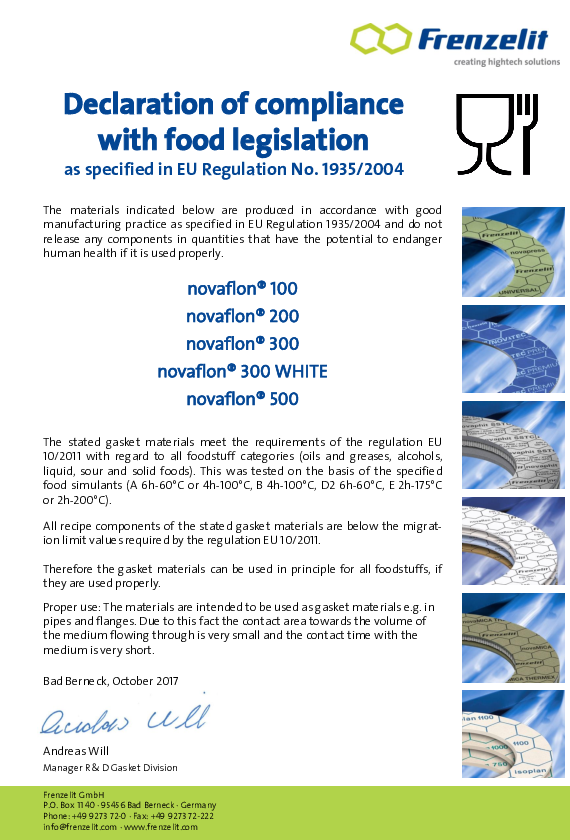

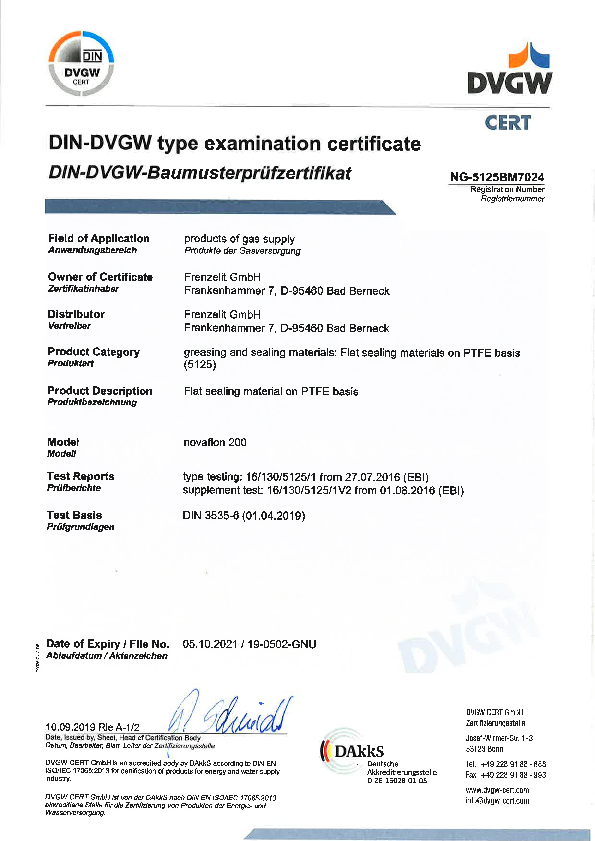

The novaflon® product line is based on modified or expanded PTFE. This material makes the gaskets resistant to most acids and alkalis throughout the entire pH range from 0 to 14. novaflon® gaskets can therefore be used universally with nearly all media and are perfect for use in the chemical industry. Moreover, novaflon® complies with Regulation (EC) No. 1935/2004 and meets the strict requirements of the FDA guideline. This means that novaflon® can be used in both food production and the pharmaceutical industry.

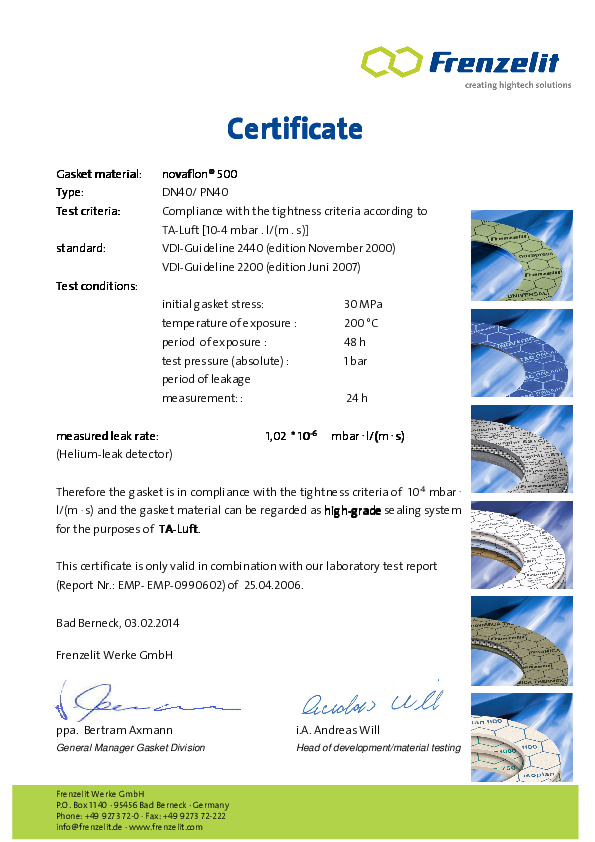

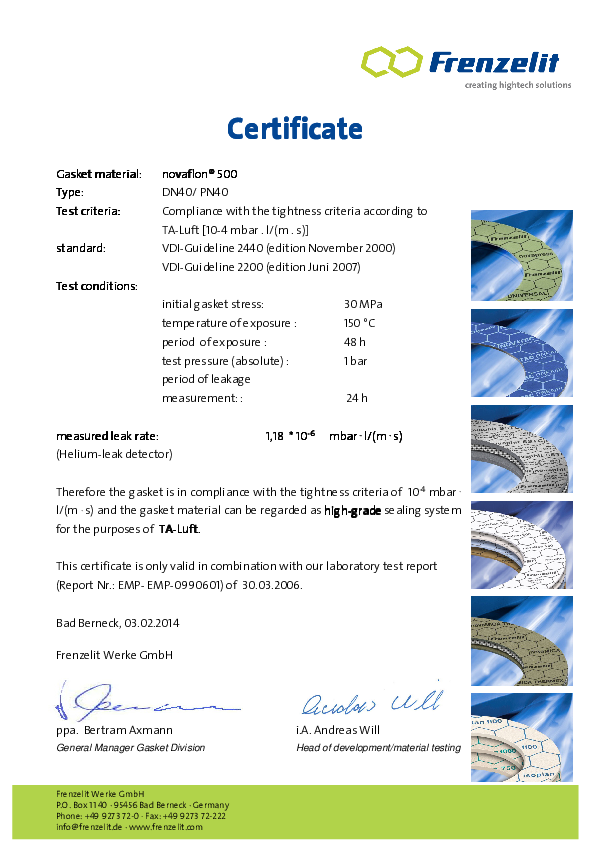

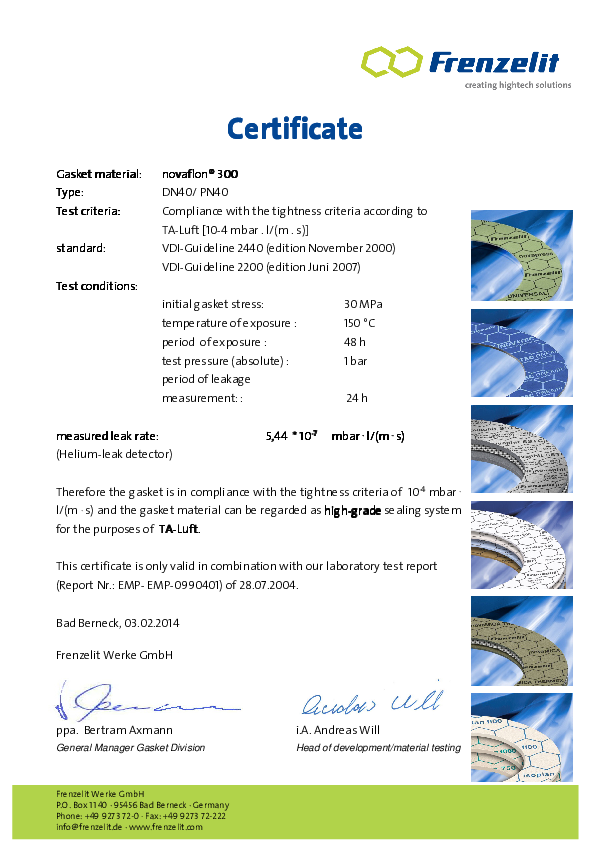

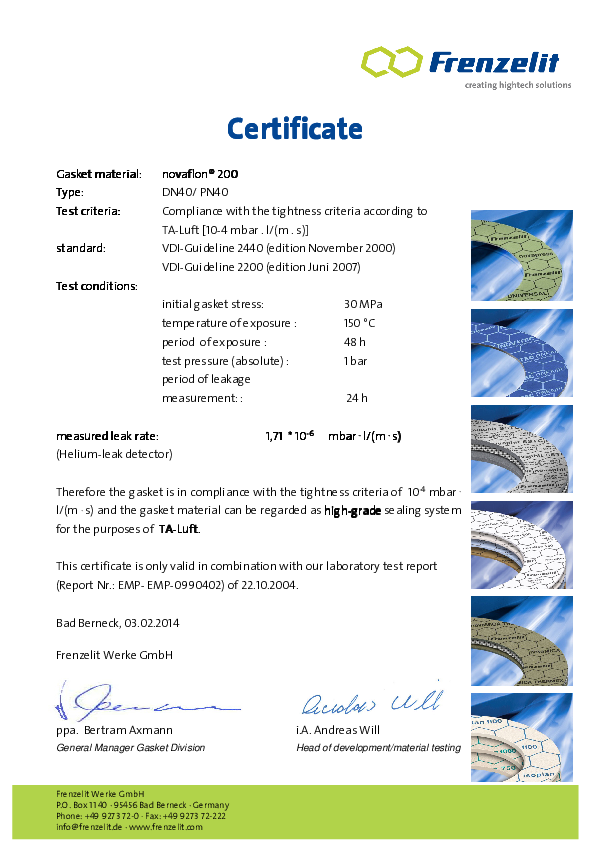

All members of the novaflon® family have excellent leakage properties and easily meet the TA Luft (German Technical Instructions on Air Quality Control) criteria [leakage rate < 10-4 mbar·l/(s·m)]. They are high quality in terms of TA Luft and make a valuable contribution to environmental protection.

novaflon® can be used in a wide temperature range from -210 °C to +260 °C and has an unlimited shelf life when stored in compliance with the recommended storage conditions according to ISO 2230.

novaflon® gaskets offer a number of key advantages over pure (virgin) PTFE produced using conventional methods:

- Stopped cold flow1 and greatly reduced hot creep2

- Resistant to high pressure and temperature loads

- High residual stress

- Good mechanical strength (even under temperature stress)

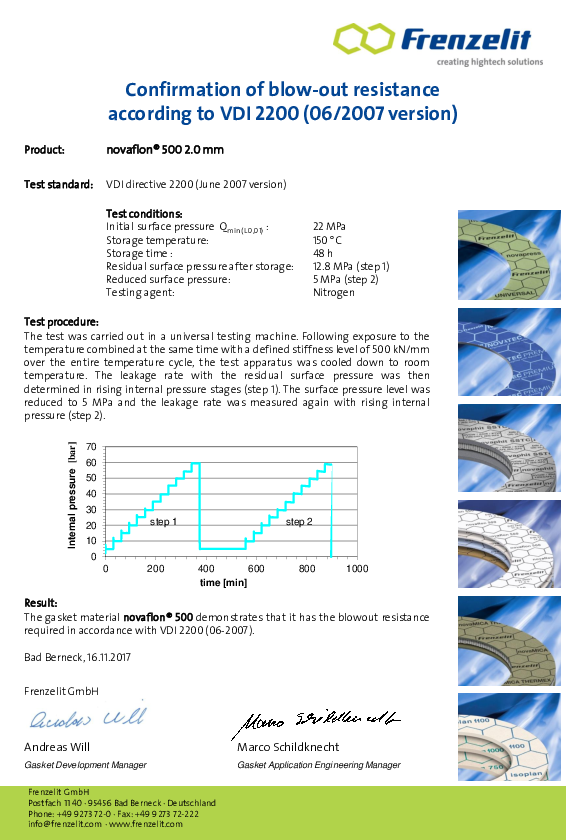

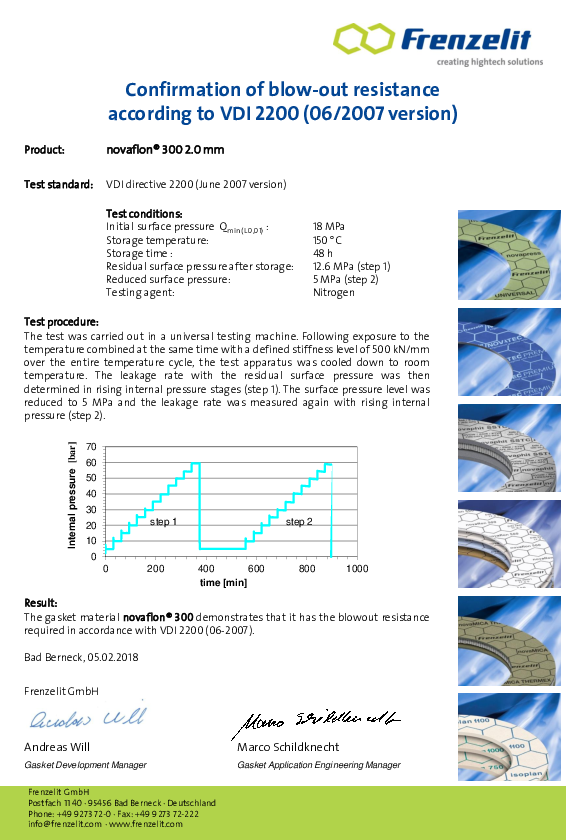

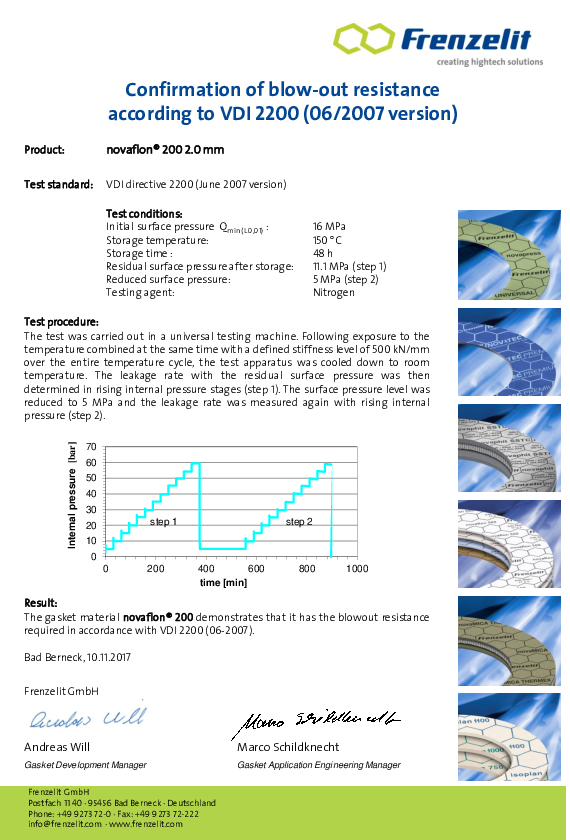

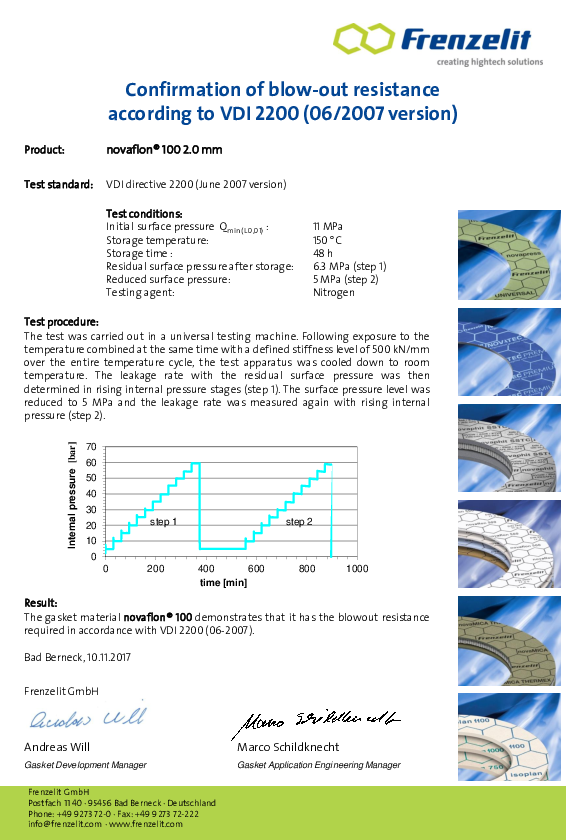

- Blow-out resistant according to VDI directive 2200

1 = Deformation under pressure exposure without heating

2 = Creep properties under pressure and temperature exposure