Mobile and emission-free thanks to electric vehicles

Electric vehicles are currently the most frequently selected option by a mobile society looking to travel in a climate-friendly manner in the future. Because, if the charging current is derived from regenerative sources, then electric vehicle mobility is CO2 neutral.

Electric drives and their units also pose special challenges for gaskets and insulation materials. Frenzelit has adapted to this new market, developing and producing customer-specific parts for special tasks in the sectors of batteries, decoupling and thermal management.

Batteries: Stored drive power

High-performance batteries can contain up to 7,000 battery cells that store the charging current. Sealing the system against moisture and environmental influences requires customized gasket solutions that ensure problem-free operation and increase service life. We see ourselves as your development partner, supporting you right from the early phases of the product creation process, to jointly develop a suitable solution for your product.

More safety in the event of fire

If a battery catches fire – due to crash damage or due to thermal events, passengers must have at least 5 minutes to leave the vehicle. If the battery is protected by Frenzelit fire protection insulation, this can add life-saving minutes. Find out more about the demanding task of fire protection for batteries in our future world “Fire protection”.

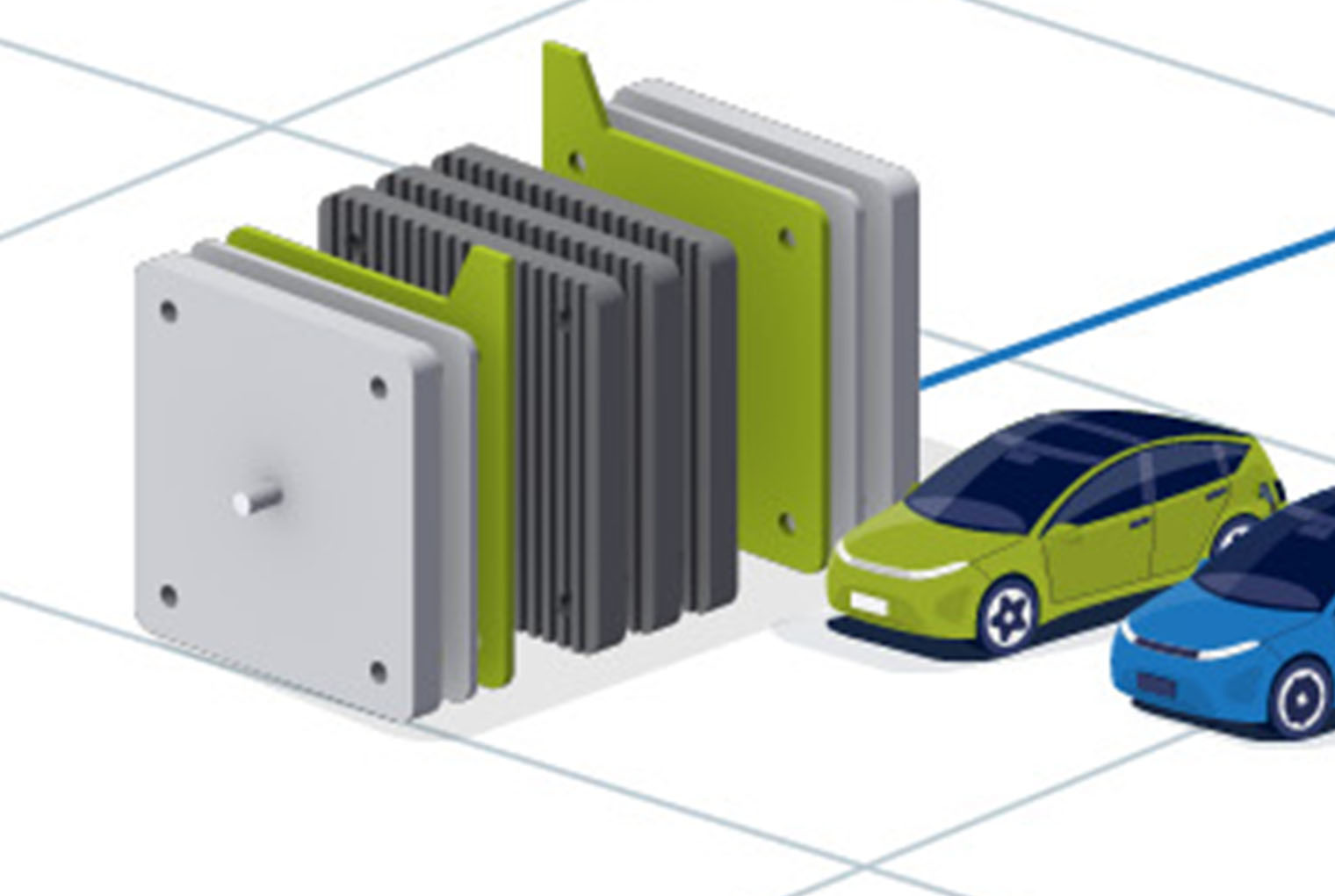

Alternative: Power from fuel cells

Hydrogen, as an energy supplier for electric motors, has the advantage that the energy quantity is also sufficient for utility vehicles, ships and aircraft. Find out more about electrolysis, fuel cells, etc. in our future world “Hydrogen” – and about corresponding Frenzelit products.

Electromagnetic compatibility

Electric motors generate fields that can interfere with vehicle electronics. The components concerned therefore need to be shielded. However, it is important that the seals on covers or housings remain conductive. Whether you need gaskets that are punched or applied as a liquid, Frenzelit materials can meet these conditions.

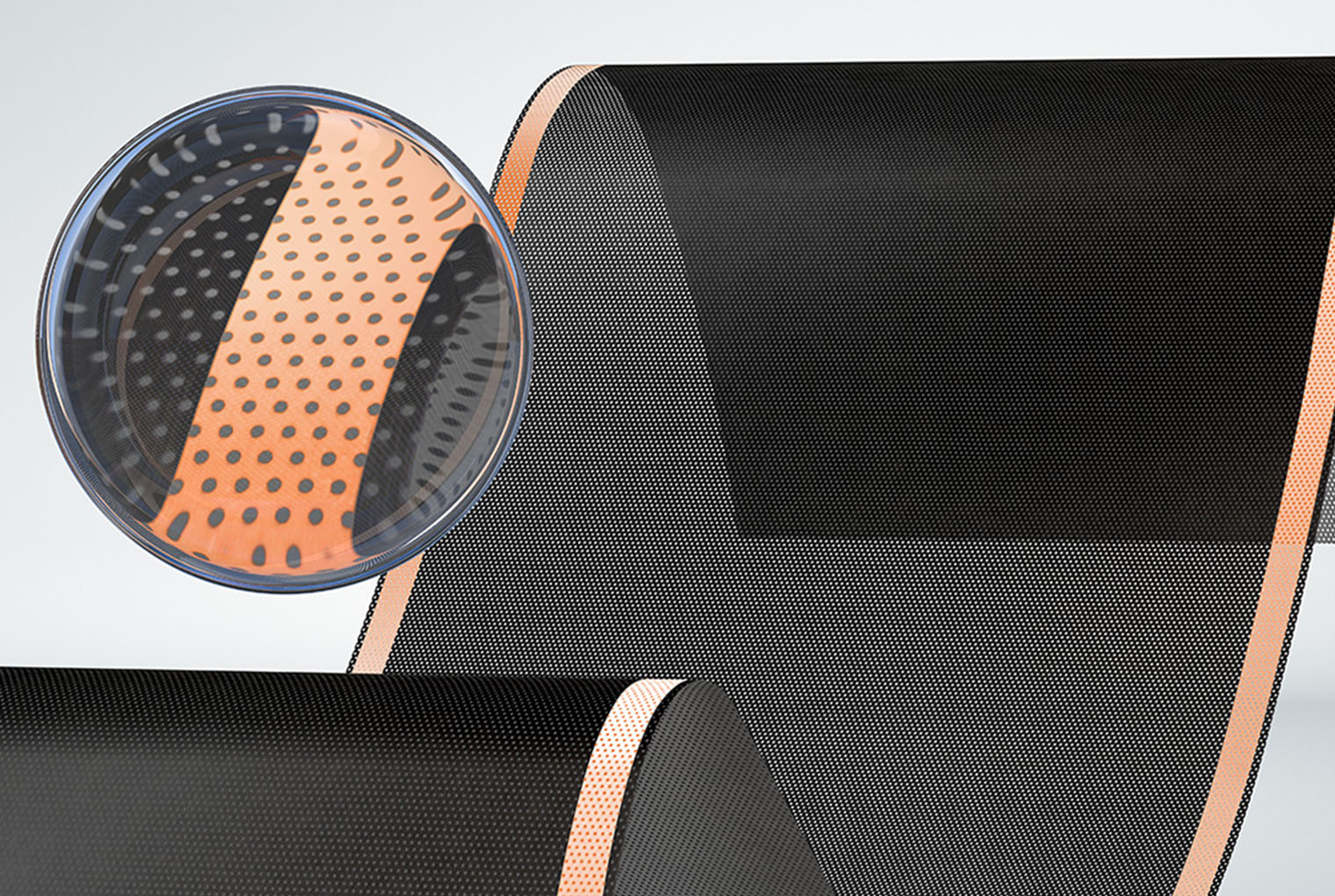

Innovation: Adjustable shielding effect

hicoTEC® EA was developed by Frenzelit as a high-tech composite material consisting of conductive carbon fibers in a matrix. Radiation control can be specifically influenced via the arrangement of the fibers.

Galvanic decoupling

Corrosion can occur at the direct contact joints of two materials with different electrochemical potentials. This problem is increasingly in focus due to the increased use of aluminum in the sector of electromobility. It can occur, for instance, between the battery and body in electric vehicles. The solution: An intermediate layer of gasket material by Frenzelit that galvanically decouples the components. As individual properties and requirements – such as creep or media resistance, for instance – can be taken into account, each solution can be customized for your system.

novaform® gasket rings prevent corrosion

As the development partner, Frenzelit discovered the ideal fiber mixture, form and delivery method suitable for the customer’s assembly process.

Electrical insulation – safety through impact protection

The sheathing of live components in crash-susceptible areas prevents passengers from coming into contact with live parts in the event of accidents. One proven material is aramid, which Frenzelit uses to produce custom-fit protective sheaths.

Practical experience Protective sheath in the Audi e-tron

Frenzelit developed the thermoREFLEX® textile aramid protective sheath for the DC-/DC converter in the electric SUV Audi e-tron.

Decoupling

Even though, in comparison to combustion engines, electric vehicles are more simple in design, transport less media and therefore need fewer gaskets, they still pose completely new challenges. For example, in the field of “Decoupling”. Our portfolio includes materials for numerous special tasks.

A quieter ride: Mechanical decoupling (NVH) and acoustic optimization

The decoupling of “Noise, Vibration, Harshness” has gained in significance for electromobility, because pump or auxiliary motor noise is no longer masked by the combustion engine. Passive structure-borne noise decoupling improves driving comfort and also prevents component wear. Various materials made by Frenzelit can contribute to numerous applications in this field.

Acoustic perception, for instance, when opening and closing doors, also always influences a vehicle’s perceived value. Frenzelit materials improve structure-borne noise decoupling. Thanks to their individual properties, including for creep, they can master even unfavorable conditions in manufacturing, like during cathodic dip coating, for example.

Practical experience Decoupling of door hinges

Our novaform® 770 material makes an important contribution to high-quality acoustic design in the automotive industry.

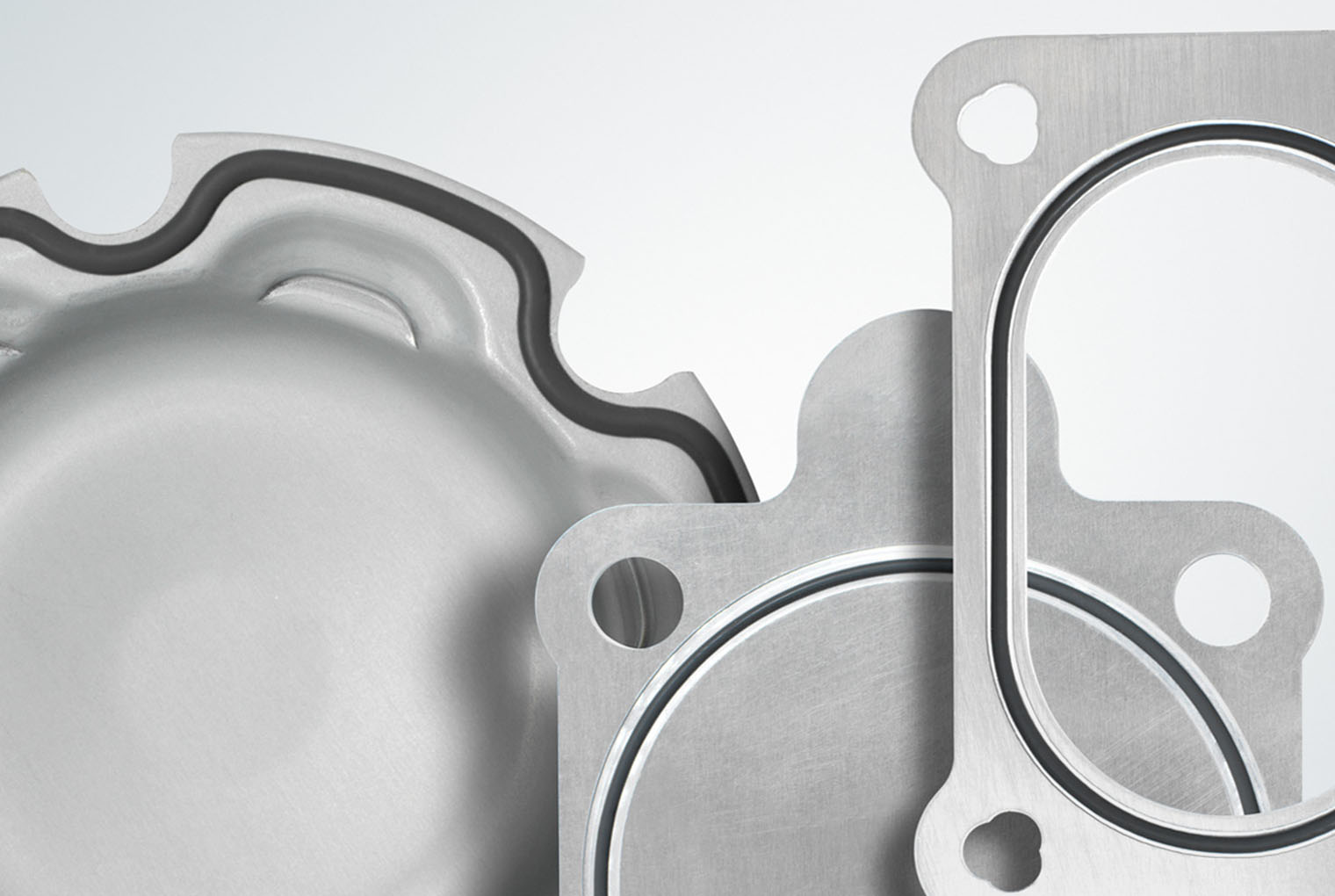

Thermal management

Electric motors and batteries all have a temperature range in which they function best. Efficiency, range and even service life decreases outside of this “perfect temperature”. Such systems are therefore cooled or heated as required in an electric vehicle. Range can be significantly extended by intelligent thermal management. Our gaskets prevent losses and increase efficiency in the necessary cooling/heating circuits.

Practical experience CO2 as a coolant

CO2 is used in heat pumps to acclimatize the interior or for the cooling of individual units. This medium poses high requirements on gasket materials because, if CO2 penetrates the gasket material, it can cause damage. This is not possible with the soft gaskets and metal bead gaskets by Frenzelit; sealing performance and durability are significantly improved.

Ultra-thin heating films

As electric vehicle motors do not generate heat to warm the interior, the ultra-thin and lightweight heating film hicoTEC® TP can provide warmth. This film can also be used to keep components, such as sensors or cameras, free of frost and operational in winter.