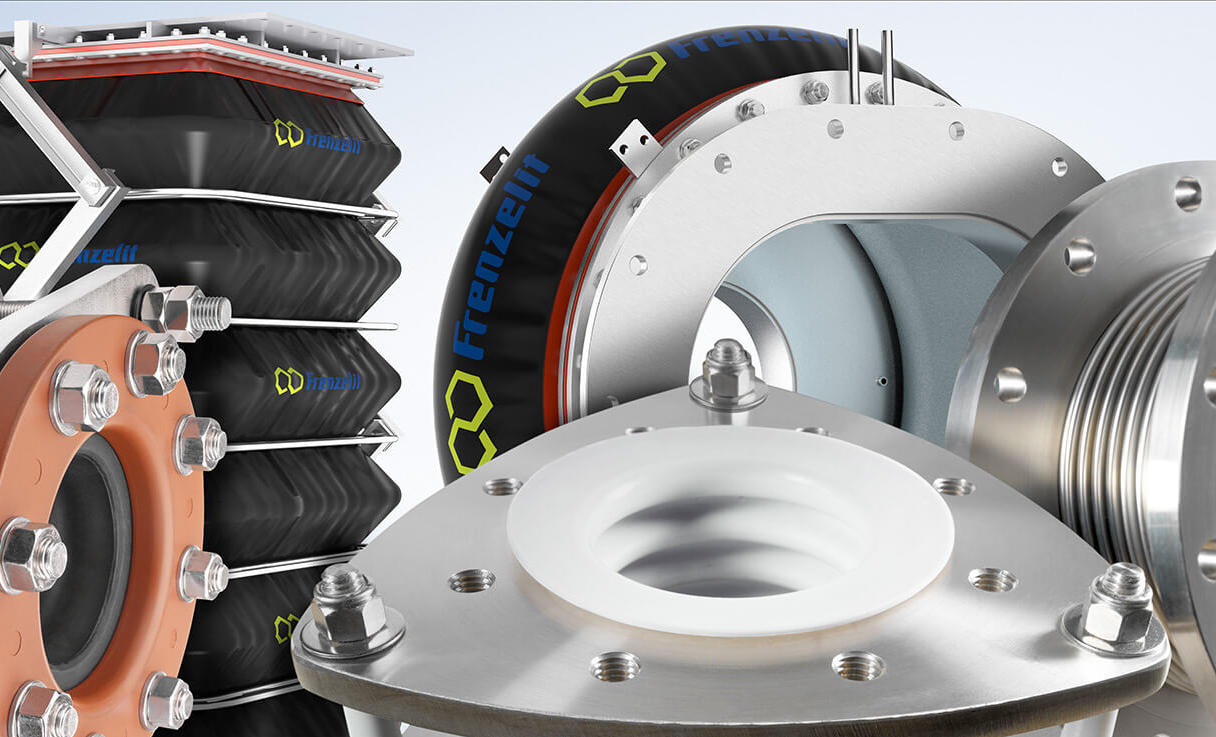

Fabric and Non-metallic Expansion Joints

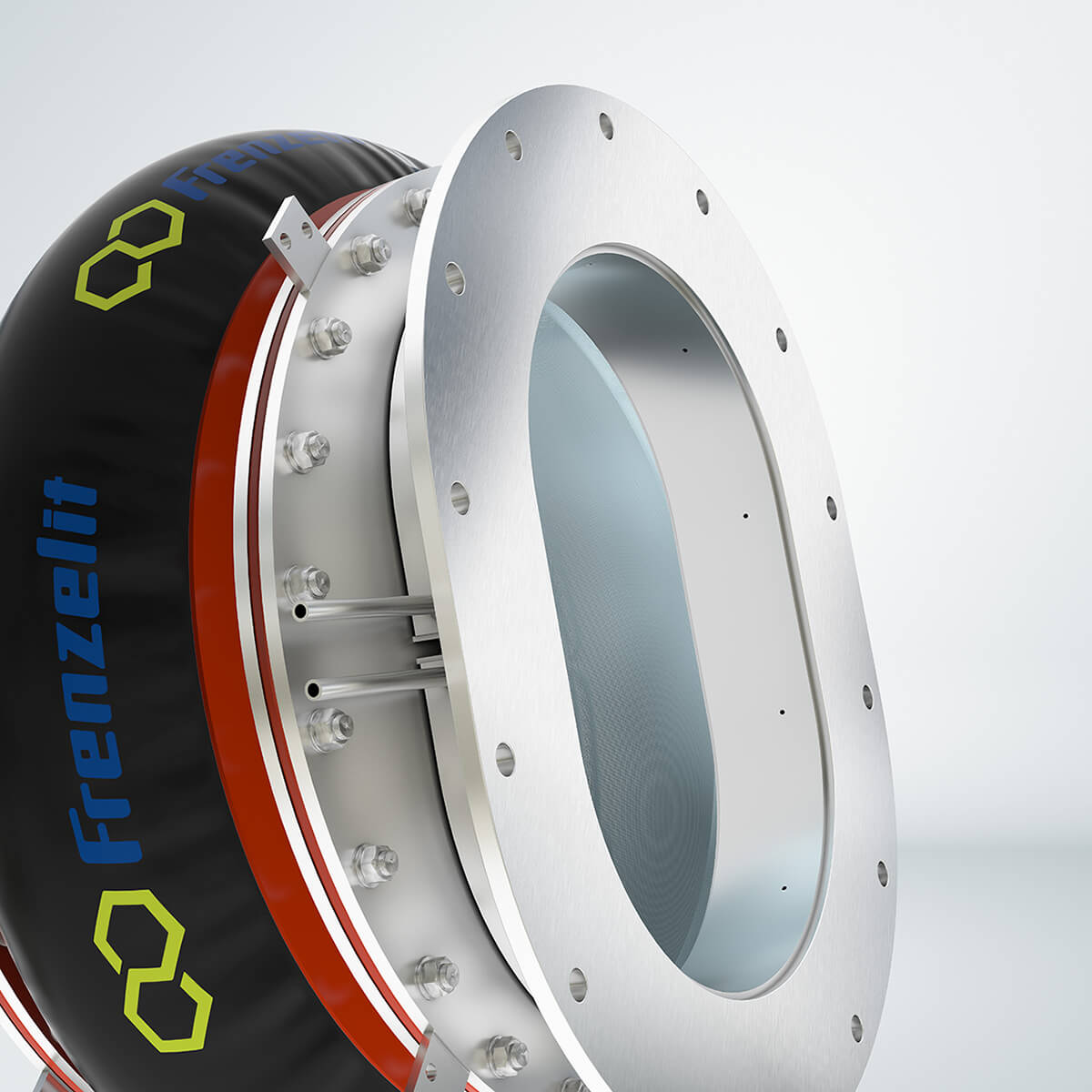

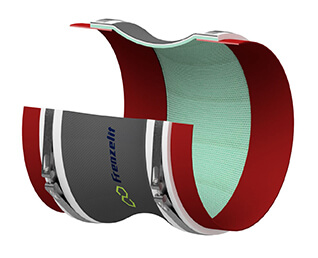

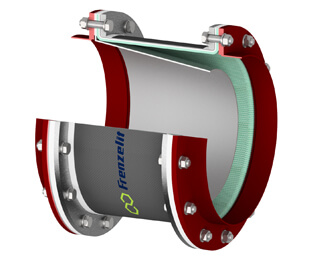

Fabric and non-metallic expansion joints must withstand loads like the system component or pipe itself and absorb additional stress, movements, oscillations or vibrations in axial and/or lateral direction – while ensuring operational safety. The main application areas are plants with gaseous media such as hot air, flue gas and acidic or alkaline gases.

To meet the highest standards, we use only the highest quality special fabrics from our own in-house production such as isoGLAS®, isoTHERM® or novatex® along with the necessary coatings.

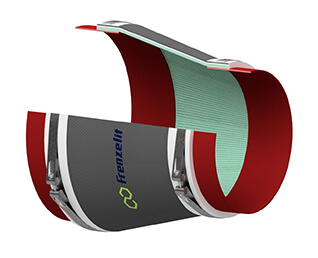

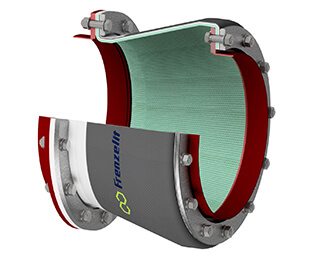

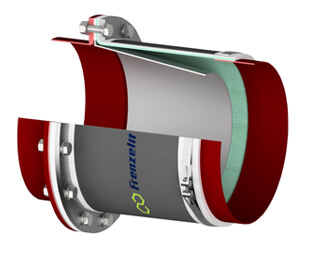

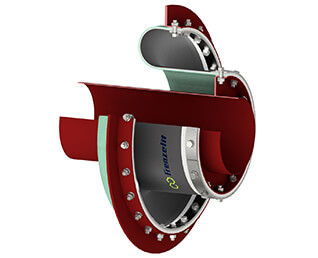

Custom material structure:

The dimensions and operating conditions in industrial plant engineering are too specific to be able to offer only standardized expansion joints. Frenzelit specializes in creating custom-designed expansion joints.

The most important prerequisites for optimal expansion joint design include precise technical information from the operator on the installation dimensions, the pressure and temperature conditions, the medium and the movements when the system is in operation. In the Documents and downloads section you will find our questionnaire with important questions on real-word conditions.

- System solutions

Fabric and non-metallic expansion joints for combined cycle gas turbine power plants (ccpp)

Fabric and non-metallic expansion joints for strip galvanizing and continuous annealing lines

Movement test – expansion joint with pantograph control guide for denitrification plant

Fabric and non-metallic expansion joints in movement test for paper industry dryer

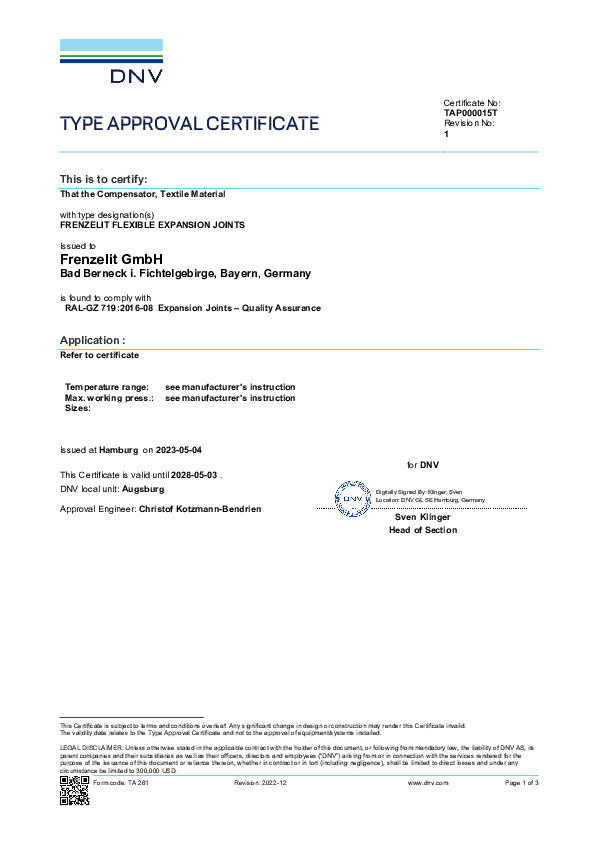

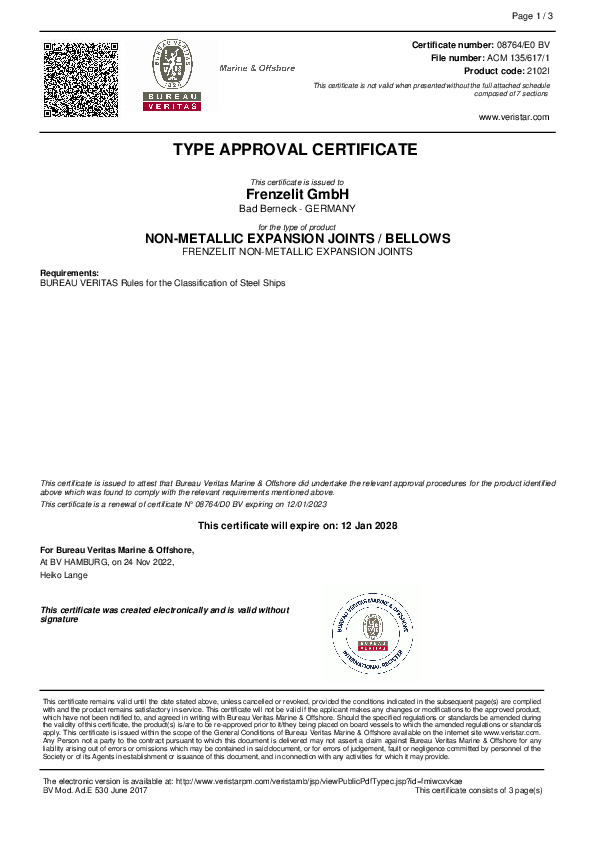

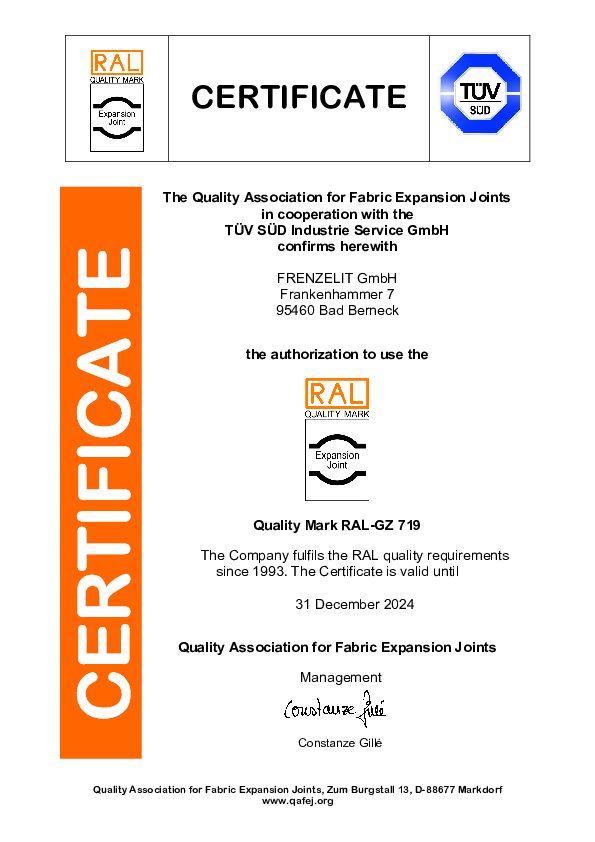

Certifications, approvals and tests:

- Application areas

Certifications, approvals and tests:

- Documents and downloads

Certifications, approvals and tests:

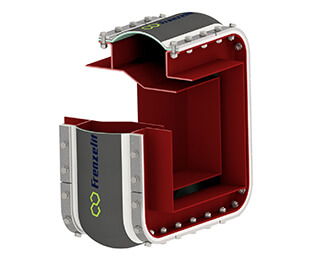

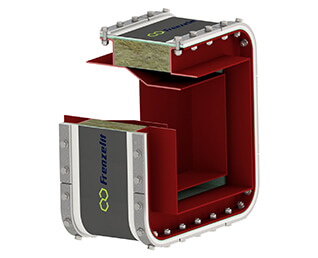

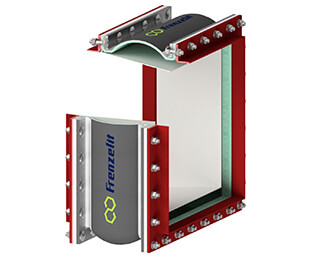

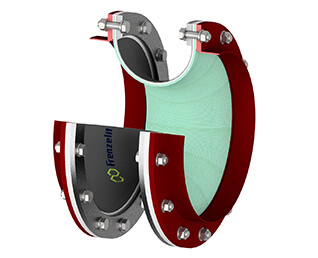

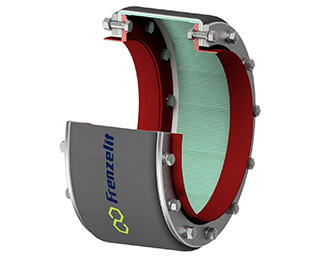

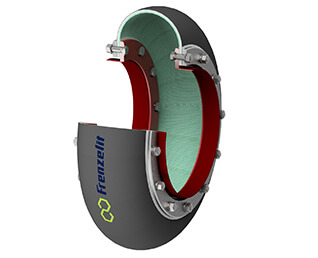

- Types

The expansion joint types, movements, temperature and pressure variations shown are only valid for the values provided in the example.

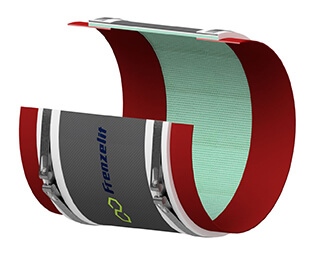

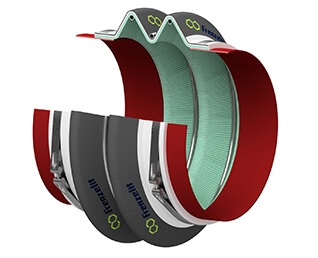

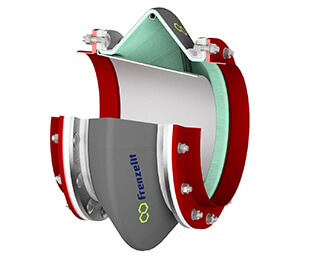

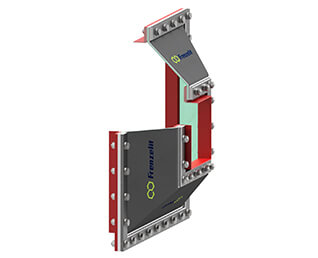

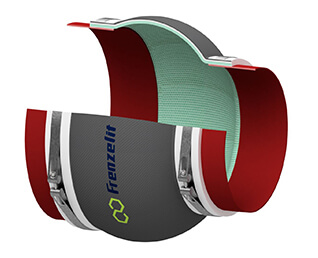

Fabric and non-metallic expansion joints may have the same construction and movement absorption, but they can be designed with a different material structure for use in different application areas.

Without flange

Expansion joint type 01.001 Movement from distance of pipe (AR) Temperature variants °F/°C Pressure variants psi/bar Axial 25% and lateral 10% 360 °F + 14,5 psi 180 °C + 1 bar 930 °F ± 1,5 psi 500 °C ± 100 mbar

Expansion joint type 01.011 Movement from distance of pipe (AR) Temperature variants °F/°C Pressure variants psi/bar Axial 35% and lateral 15% 360 °F + 14,5 psi 180 °C + 1 bar 930 °F ± 1,5 psi 500 °C ± 100 mbar

Expansion joint type 01.001 + 1.001/IS Movement from distance of pipe (AR) Temperature variants °F/°C Pressure variants psi/bar Axial 25% and lateral 10% 360 °F + 14,5 psi 180 °C + 1 bar 1830 °F ± 1,5 psi 1000 °C ± 100 mbar

Expansion joint type 1.011/IS Movement from distance of pipe (AR) Temperature variants °F/°C Pressure variants psi/bar Axial 35% and lateral 15% 360 °F + 14,5 psi 180 °C + 1 bar 1830 °F ± 1,5 psi 1000 °C ± 100 mbar

Expansion joint type 01.041 + 1.041/IS Movement from distance of pipe (AR) Temperature variants °F/°C Pressure variants psi/bar Axial 35% and lateral 15% 360 °F + 14,5 psi 180 °C + 1 bar 1830 °F ± 1,5 psi 1000 °C ± 100 mbar With flange

Expansion joint type 01.201 Movement from flange distance (EH) Temperature variants °F/°C Pressure variants psi/bar Axial 25% and lateral 10% 360 °F + 14,5 psi 180 °C + 1 bar 930 °F ± 1,5 psi 500 °C ± 100 mbar

Expansion joint type 01.211 Movement from flange distance (EH) Temperature variants °F/°C Pressure variants psi/bar Axial 35% and lateral 15% 360 °F + 43,5 psi 180 °C + 3 bar 930 °F ± 1,5 psi 500 °C ± 100 mbar

Expansion joint type 01.251 Movement from flange distance (EH) Temperature variants °F/°C Pressure variants psi/bar Axial 70% and lateral 30% 360 °F - 7,25 psi 180 °C - 0,5 bar 930 °F ± 1,5 psi 500 °C ± 100 mbar

Expansion joint type 01.301 Movement from flange distance (EH) Temperature variants °F/°C Pressure variants psi/bar Axial 25% and lateral 10% 360 °F + 14,5 psi 180 °C + 1 bar 480 °F ± 2,9 psi 250 °C ± 200 mbar

Expansion joint type 01.351 Movement from flange distance (EH) Temperature variants °F/°C Pressure variants psi/bar Axial 70% and lateral 30% 360 °F + 72,5 psi 180 °C + 5 bar 930 °F ± 1,5 psi 500 °C ± 100 mbar For large movements

Expansion joint type 01.031/2 Movement from distance of pipe (AR/EH) Temperature variants °F/°C Pressure variants psi/bar Axial 70% and lateral 30% 360 °F + 14,5 psi 180 °C + 1 bar 750 °F ± 2,9 psi 400 °C ± 200 mbar

Expansion joint type 01.231 Movement from distance of pipe (AR/EH) Temperature variants °F/°C Pressure variants psi/bar Axial 60% and lateral 30% 360 °F + 14,5 psi 180 °C + 1 bar 750 °F ± 2,9 psi 400 °C ± 200 mbar

Expansion joint type 01.422 Movement from distance of pipe (AR/EH) Temperature variants °F/°C Pressure variants psi/bar Axial 100% and lateral 10% 360 °F + 43,5 psi 180 °C + 3 bar 930 °F ± 1,5 psi 500 °C ± 100 mbar Special versions

Expansion joint type 01.012 Movement from distance of pipe (AR/EH) Temperature variants °F/°C Pressure variants psi/bar Axial 80% and lateral 20% 360 °F + 14,5 psi 180 °C + 1 bar 930 °F ± 1,5 psi 500 °C ± 100 mbar

Expansion joint type 01.022 Movement from distance of pipe (AR/EH) Temperature variants °F/°C Pressure variants psi/bar Axial 50% and lateral 20% 360 °F + 14,5 psi 180 °C + 1 bar 930 °F ± 1,5 psi 500 °C ± 100 mbar

Expansion joint type 01.421 Movement from distance of pipe (AR/EH) Temperature variants °F/°C Pressure variants psi/bar Axial 30% and lateral 10% 360 °F + 14,5 psi 180 °C + 1 bar 480 °F ± 2,9 psi 250 °C ± 200 mbar

Expansion joint type 01.101 Movement from distance of pipe (AR/EH) Temperature variants °F/°C Pressure variants psi/bar Axial 25% and lateral 10% 360 °F + 14,5 psi 180 °C + 1 bar 930 °F ± 1,5 psi 500 °C ± 100 mbar

Expansion joint type 01.072 Movement from distance of pipe (AR/EH) Temperature variants °F/°C Pressure variants psi/bar Axial 80% and lateral 20% 360 °F + 7,25 psi 180 °C + 0,5 bar 930 °F ± 1,5 psi 500 °C ± 100 mbar Certifications, approvals and tests:

- Service

Service

Expansion joints must withstand loads like the system component or pipe itself absorb and additional stress, movements, oscillations or vibrations in axial and/or lateral direction – while ensuring operational safety.

You may already have a very good idea what your expansion joint should look like. Or an application that you want to further develop. A partnership with Frenzelit allows you to realize your ideas according to your system-specific requirements.

We offer you the following:

Frenzelit engineers work together with your design department to develop a technically and economically feasible solution that meets your demands. Our experts are at your disposal in all project phases to develop fabric, non-metallic and elastomer expansion joints, PTFE and multi-laminated PTFE expansion joints as well as rubber and metal expansion joints for your system. We are with you every step of the way – from planning and production to installation and maintenance – for the life of your system.Personal, on-site consulting ensures that your employees stay focused on what they do best, saves valuable resources and gets you the results you need faster. We develop, design or optimize expansion joints in collaboration with your team based on your specifications – so you can rest assured that they will continue to meet tomorrow’s demands. That’s why our motto is “creating hightech solutions”.

Find out more about Frenzelit customer and installation services

Certifications, approvals and tests:

![[Translate to english USA:] Frenzelit Gewebekompensatoren als Abdichtung im Gaskanal / Schiffskonstruktion Gas duct design in shipbuilding](/fileadmin/user_upload/csm_mobilitaet_weichstoffkompensator_frenzelit_6_4618e0ae36.jpg)