Revolutionary heating films and heating systems made of innovative composite materials

hicoTEC® TP combines the thermal-electric function of a radiant heating system with the application advantages of an ultra-thin film. Our patented production method enables particularly uniform distribution of conductive fibers across the surface. Sheet resistance, voltage and heating capacity are configurable, even though the film is unusually thin: The perfect material for heating very small to very large surfaces. hicoTEC® TP Thermal Power delivers warmth almost invisibly to wherever it is needed.

3 to 4000 Ω/sqr

4 to > 400 V

up to > 20 W/cm²

How can we support you?

Heating films and heating systems for buildings

hicoTEC TP®Heating films based on carbon fibers generate healthy and uniformly radiated heat at a safe low voltage. The installation height of just 0.4 mm is extremely low, allowing the heating film to be integrated almost invisibly in plaster or tiling adhesive. The heating effect is not affected by any cut-outs or boreholes in the film.

More about the advantages of a building heating system using hicoTEC® TP

A heating film that can be directly integrated in the plaster or tiling adhesive? Only available from Frenzelit!

Heating films in the mobility and automotive industry

Well-known recreational vehicle manufacturers use Frenzelit heating films as auxiliary heating in their floor construction. hicoTEC® TP is just 0.4 mm thick and can be almost invisibly and easily integrated. The necessary stability is ensured by the carbon fibers. Comfort in RVs traveling in colder regions is noticeably increased without significantly adding to the weight of the vehicle.

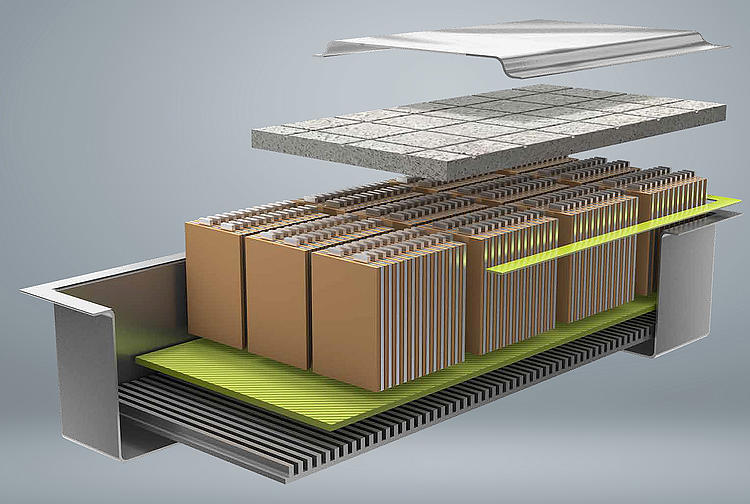

The product is also suitable in the vehicle industry for regulating the temperature of critical components. Electric vehicle batteries, for instance, work best in the temperature range between 20 and 40 °C, so auxiliary heating can improve range and efficiency when outdoor temperatures are low. Heating is also useful for and critical to the safety of other batteries or liquid containers. The flexible hicoTEC® TP film can adapt perfectly to delicate components such as sensors and external cameras. As electric vehicle motors do not generate heat to warm the interior, efficient lightweight heating systems are essential. hicoTEC® TP heating films ensure that comfortable warmth does not affect the driving range, thanks to their low weight and energy consumption.

hicoTEC® TP keeps the entry area of railway wagons ice-free and floor heating in the passenger compartment provides warmth: More safety and comfort for passengers.

We have worked successfully with the Frenzelit team for years now. Especially worthy of mention are the extremely collaborative partnership, exceptional reliability and the consistently high quality of the results they produce. On top of all this, they never fail to impress us with exciting innovations that feature truly relevant customer benefits.

Sometimes every millimeter and every gram counts for building work. This is where our ultra-thin and light heating film shines.

Heating films and heating elements in industry

hicoTEC® TP is suitable for temperature applications up to 250° C with variable operating voltages up to 400 V and heating capacities above 20 W/cm². In order to keep your process and your machine within the optimal temperature range, we develop and manufacture customer-specific heating elements ranging from custom-made heating films right up to ready-to-connect heating plates. Substances, for instance, can be kept at the perfect temperature for the next process step by heating the complete surface of pipes. Industrial dry rooms can also be heated with hicoTEC® TP. Heating elements can be individually customized depending on geometry and heating capacity requirements. Take advantage of our customized solutions:

- Ready-made heating films for working temperatures of up to 250° C

- Integrated temperature safeguard or temperature control possible

- Compact heating elements with insulation on the back

- Engineering services from design to type testing